Products

-

feed mixer pellet mill blender TMR feed mixer

The all-in-one feed preparation machine is mainly used for the processing and preparation of feed in livestock farms and has the following multiple functions: Mixing feed: It can thoroughly mix and stir various dry forages, crop straws, silage and other fibrous feeds and concentrated feeds in a certain proportion, ensuring that the roughage and concentrated feeds are evenly mixed, preventing animals from being picky eaters, and guaranteeing a balanced intake of nutrients for the animals. Chop... -

bag pulse dust collecter pulse bag dust collecter dust collecter

The following is a detailed introduction to bag filters:

<ul><li><strong>Basic Introduction</strong>1<ul><li><strong>Definition</strong>: A bag filter, also known as a filtration dust collector, is a purification equipment that uses organic or inorganic fiber filter cloth to filter out dust from gas. It belongs to a widely used dry dust filtration device.</li></ul><ul><li><strong>Development History</strong>: In the 1780s, Germany was the first to apply it commercially. In 1954, the invention of reverse jet blowing cleaning technology and in 1957, the invention of pulse-jet bag dust removal technology achieved major breakthroughs. In the 1970s, it gradually developed towards large-scale. In the 1950s, China began to turn to bag filters under the influence of foreign countries. In the 1960s, it entered the initial stage and has been continuously developed and innovated sin -

Magnetic separator Mine magnetic separator Dry magnetic separator

Dry magnetic separator working principle 1

A strong magnetic field is generated inside the magnetic separator through a permanent magnet or electromagnet. When the mixed material containing magnetic minerals and non-magnetic minerals enters the magnetic field area of the magnetic separator, the magnetic minerals are attracted by the magnetic force, move along the magnetic field direction, and are collected by the magnetic roller or magnetic plate of the magnetic separator, while the non-magnetic minerals are not affected by the magnetic force, continue to move along the original direction of movement, and discharge from the magnetic field area.

Taking the wet permanent magnet drum magnetic separator as an example, after the slurry flows into the tank through the feed box, the ore particles enter the tank in a loose state under the action of the water flow of the feed pipe. Under the action of the magnetic field, the magnetic particles occur and form a “magnetic group” or “magnetic chain”, and move towards the magnetic pole, and are adsorbed on the cylinder. Because the polarity of the magnetic poles is alternately arranged along the rotation direction of the cylinder, the “magnetic group” or “magnetic chain” will produce magnetic agitation when rotating with the cylinder, and the non-magnetic minerals such as gangue that are included in it will fall off during the flip. In the end, the “magnetic group” or “magnetic chain” that is sucked on the surface of the cylinder is the concentrate, the concentrate is transferred to the magnetic edge of the magnetic system with the weakest magnetic force, and is unloaded into the concentrate tank under the rinsing water flow of the discharge pipe, and the non-magnetic or weakly magnetic minerals are left in the slurry with the slurry discharged outside the tank and become the tailings.

Category 1 -

Magnetic separator

Magnetic separator is a mineral processing work that uses the magnetic difference of minerals to screen in an uneven magnetic field. The main components of the magnetic separator are magnetic system, sorting box and feeding box. Under the action of the magnetic field, the magnetic mineral particles are magnetized, attracted by the strong magnetic field, adsorbed on the surface of the cylinder, and rotate with the cylinder. When the magnetic mineral particles rotate to the outlet of the magnetic system, because the magnetic force is weakened and the water is washed, the magnetic adsorption will be removed and then discharged into a concentrate

-

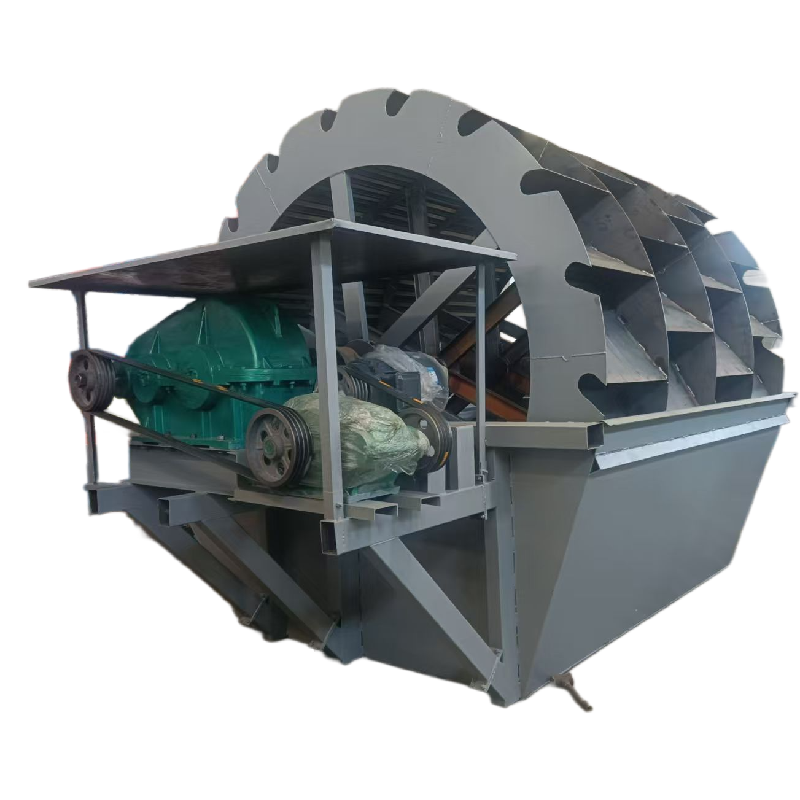

sand washing machine Bucket sand washing machine

Working principle of wheel bucket sand washing machine

Mixing and separation: The sand to be cleaned enters the washing tank of the sand washing machine from the feed port. At the same time, the washing tank will continue to inject clean water to make the sand suspended and stirred in the water. Driven by the motor, the blades on the wheel bucket drive the wheel bucket to do circular motion in the washing tank to stir and flip the sand material. In this process, impurities such as soil and dust in the sand will be separated from the sand under the scouring of water and the stirring of the wheel bucket, and the impurities will form a slurry shape with the water.

-

Flat Mode Electric Diesel Pellet Granulating Machine Biomass Feed Processing Equipment For Animal

Company Profile Customer Visit Overseas Delivery Exhibition Feedback -

Efficient Cutting Suitable For Large Scale Production Grass Powder Machine Powerful Straw Crusher

A hay cutter is an agricultural equipment specially used to cut plant materials such as hay and silage into small pieces for animal feeding and storage. It achieves fast cutting through efficient knives and feeding systems, saving time and labor. Hay cutters usually have the function of adjustable cutting length to meet the needs of different animals. They are widely used in the breeding industry to help improve feed utilization.

-

Pressure Resistance Briquetting Machine Grass Processing Machine Stable Practical Mixing Machine Hot Sale Uniform Briquetting

A briquetting machine is a device used to compress loose materials into dense blocks or spheres. It is widely used in industries such as biomass, metal, coal powder, and mineral powder. It compresses large waste, powder or granular materials into regular shapes through different methods such as hydraulic, mechanical or high pressure, so as to facilitate transportation, storage or subsequent processing. The briquetting machine can not only improve the utilization rate of materials and reduce the volume of waste, but also reduce transportation and storage costs and improve production efficiency.

Depending on the material, briquetting machines can be divided into biomass briquetting machines, metal briquetting machines, coal powder briquetting machines and other types. The equipment has a compact design and a solid structure. It usually adopts automatic control and has the characteristics of high efficiency, energy saving and durability. During operation, the briquetting machine uses high pressure to make the materials tightly combined, and the molding effect is good. The pressed block material has high density and high strength, which is conducive to subsequent processing or direct application.

The briquetting machine not only saves resources and improves efficiency in industrial production, but also has good environmental benefits. By briquetting waste materials, the discharge of waste is reduced, which meets the requirements of green environmental protection in modern production and is an important equipment in the sustainable development production system.

-

Stable Beaters Crusher Specialized Straw Crusher Grinder Hammer Crusher Grass Bale Cutter

A hammer mill is a versatile and powerful machine used in various industries for grinding, crushing, and pulverizing materials into smaller, more manageable particles. The fundamental design of a hammer mill consists of a rotor with swinging hammers attached, which rotates at high speed within a chamber. As the rotor spins, the hammers strike the material fed into the mill, breaking it down through impact and shear forces.

-

LS screw conveyor: working principle and application, ideal choice for efficient material transportation

LS screw conveyor is a mechanical equipment used for conveying powder, granular and small block materials horizontally or at a small angle. It has a simple design structure and is easy to operate and maintain. It is widely used in the material conveying process of building materials, chemical industry, metallurgy, food, environmental protection and other industries.

-

Optimize your production process: Advantages of electromagnetic feeder, electromagnetic feeder improves material conveying efficiency

Electromagnetic feeder is a device that conveys materials through the principle of electromagnetic vibration. It uses the periodic magnetic field of the electromagnet to make the material trough vibrate at high frequency, thereby conveying the material evenly and continuously to the desired location. Electromagnetic feeder has the advantages of simple structure, convenient adjustment, uniform conveying, low energy consumption, etc. It is widely used in mining, metallurgy, coal, building materials, chemical industry and other industries.

-

How to properly maintain and service GS screw conveyor, improve production efficiency of GS screw conveyor

GS type screw conveyor is a common material conveying equipment, mainly used for conveying powder, granular and small block materials. It is widely used in building materials, chemical industry, electric power, metallurgy, coal mining and other industries. GS type screw conveyor has been widely used in many industries due to its high efficiency and reliability. Correct installation and maintenance can extend the service life of the equipment and improve production efficiency.