Buyers Most Advanced Mining Ball Mills

Buyers Most Advanced Mining Ball Mills,

Buy advanced mining ball mill Where can I buy advanced mining ball mill Best price for advanced mining ball mill Top mining ball mill for sale Purchasing advanced mining ball mills Buy advanced mining,

Detailed Professional Introduction

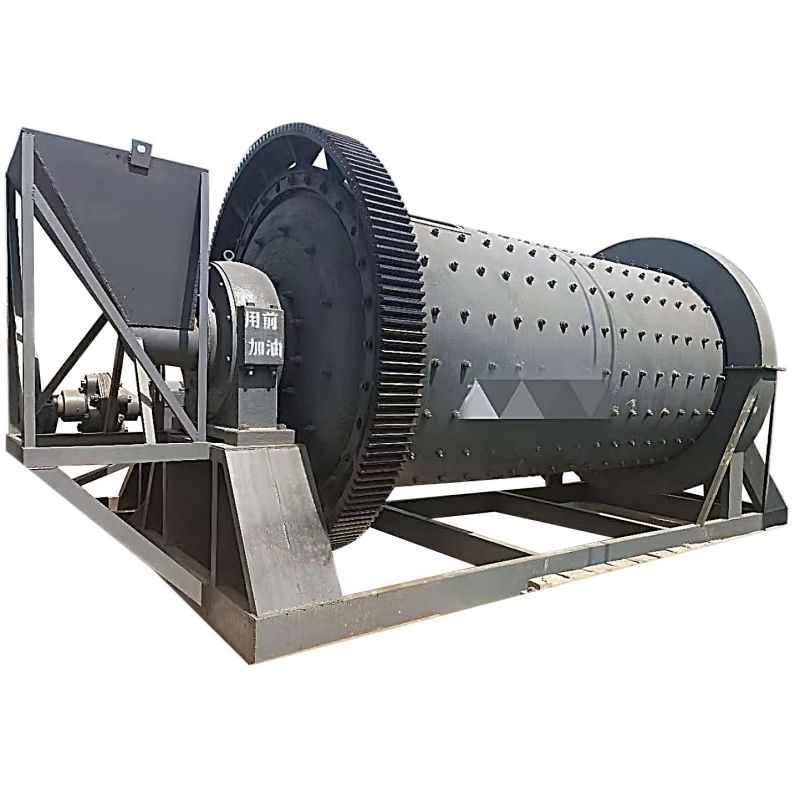

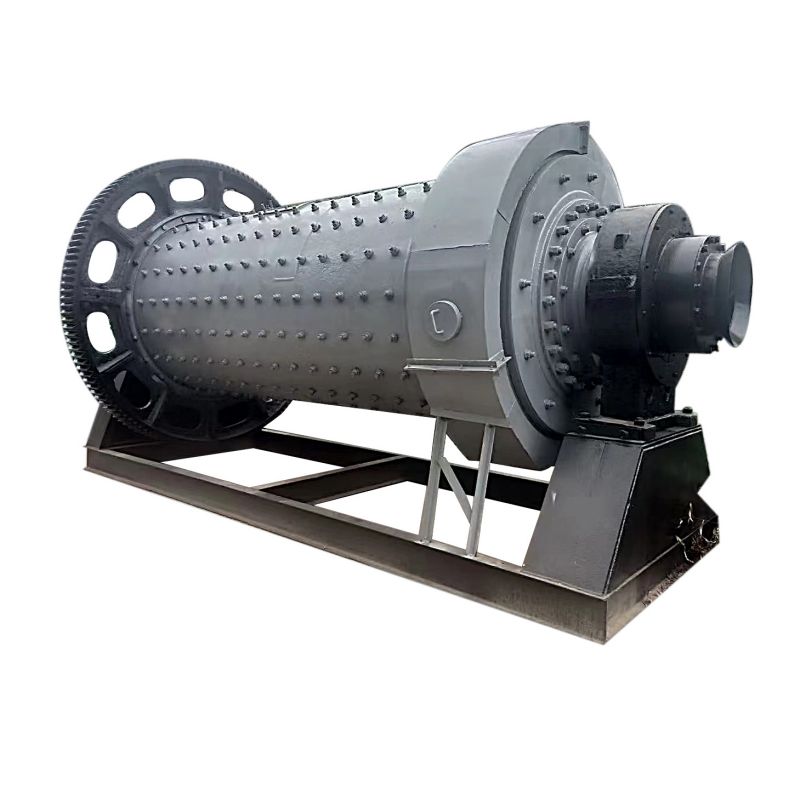

The ball mill, an intricate and sophisticated grinding device, serves as a cornerstone in countless industrial processes. Designed with a cylindrical container, it revolves around its axis, enabling the grinding and mixing of materials to achieve desired particle sizes and chemical compositions.

Within the ball mill, the grinding process occurs through the impact and attrition of the grinding media. The media, typically in the form of steel balls, ceramic balls, or rods, are placed in the rotating cylinder. As the mill rotates, the grinding media cascade and tumble, colliding with the material to be ground. This collision causes the material to break and undergo size reduction, resulting in the desired particle size distribution.

The ball mill’s efficiency and versatility are evident in its ability to handle both dry and wet grinding processes. In dry grinding, the material and grinding media are introduced into the mill without any additional liquid. This allows for efficient comminution of the particles and is commonly employed in applications where moisture control is critical. Conversely, wet grinding involves the addition of a liquid medium, such as water or a solvent, to the mill. This liquid not only aids in reducing particle size but also helps control the temperature generated during the grinding process and minimizes the generation of dust.

Optimizing the performance of a ball mill involves careful consideration of various factors. The speed of rotation, size and composition of the grinding media, duration of grinding, and properties of the material being processed all contribute to the overall effectiveness of the mill. By understanding and manipulating these parameters, professionals can tailor the operation of the ball mill to achieve desired grinding efficiency, product quality, and throughput.

The ball mill finds extensive applications across a wide range of industries, including mining, pharmaceuticals, ceramics, and chemical engineering. Its ability to produce fine particle sizes and homogeneous compositions makes it indispensable in processes involving materials like minerals, ores, pigments, and chemicals.

Professionals working in fields such as process engineering, materials science, and manufacturing understand the importance of comprehending the intricate workings of the ball mill. By studying the operational principles, exploring advanced techniques, and optimizing various parameters, professionals can unlock the full potential of the ball mill for specific applications, leading to enhanced productivity, product quality, and process optimization.

In conclusion, the ball mill represents a critical tool in various industrial processes, enabling efficient grinding, blending, and particle size reduction. Its versatility, reliability, and capacity to handle different grinding processes make it indispensable in scientific research, manufacturing, and production. By continuously advancing our knowledge and understanding of the ball mill, professionals can further harness its capabilities and optimize its performance to meet the evolving needs of industry and technology.

Our Factory

Precision and superior engineering, our mining ball mills are specially designed to meet the stringent requirements of the mining industry. Through our relentless focus on quality and performance, we create products that exceed industry standards.

One of the key features that set our ball mills apart is their exceptional durability. These ball mills are constructed of high-quality materials to withstand the harsh operating conditions of mining sites. Whether crushing, grinding or pulverizing, our ball mills are up to the task, delivering consistent results day in and day out.

Advanced technology integrated in our mining ball mills ensures optimum efficiency and performance. Our mills are capable of finely grinding a wide variety of materials, enabling miners to extract valuable minerals with the highest precision. State-of-the-art control systems allow for seamless operation, reducing the risk of downtime and maximizing production.

Safety is paramount in the mining industry and our mining ball mills are designed with this principle in mind. Our factories are equipped with strong safety measures such as emergency stop buttons and protective guards, prioritizing the well-being of the operators. These safety features are complemented by a user-friendly interface that makes our ball mills convenient and easy to operate.

Additionally, our mining ball mills are engineered for versatility. With adjustable settings, operators can tailor the grinding process to meet specific requirements, ensuring the best results for a wide variety of minerals and ores. From large mining operations to small projects, our ball mills are available to suit different needs, giving our customers maximum flexibility.

In addition to superior performance, our ball mills for mining also prioritize energy efficiency. By utilizing cutting-edge technology, these ball mills minimize energy consumption, thereby providing mining companies with significant cost savings. Our commitment to environmental sustainability is reflected in the design of our products.

With buyers state of the art mining ball mills, you can start your mining project with confidence. Our reliable, efficient plants provide a competitive advantage, enabling you to maximize productivity while minimizing operating costs. Backed by our expert team and comprehensive customer support, you can rely on us for your mining needs.

In conclusion, state-of-the-art mining ball mills for buyers represent the epitome of technological advancement in the mining industry. Unsurpassed in durability, efficiency and versatility, these ball mills provide unrivaled performance for mining operations worldwide. Invest in our mining ball mills and experience the difference in productivity and profitability.