Factory Outlets Industry Rapid Mixer Granulator Machine

To become the stage of realizing dreams of our employees! To build a happier, a lot more united and more expert workforce! To reach a mutual profit of our buyers, suppliers, the society and ourselves for Factory Outlets Industry Rapid Mixer Granulator Machine, We believe that a passionate, revolutionary and well-trained team should be able to set up very good and mutually useful business relationships along with you soon. Remember to really feel no cost to get in touch with us for more facts.

To become the stage of realizing dreams of our employees! To build a happier, a lot more united and more expert workforce! To reach a mutual profit of our buyers, suppliers, the society and ourselves for China Granulator Machine and Rapid Mixer Granulator Machine, Look forward to the future, we are going to focus more on the brand building and promotion . And in the process of our brand global strategic layout we welcome more and more partners join us, work together with us based on mutual benefit. Let’s develop market by fully utilizing our comprehensive advantages and strive for building.

Product Advantages

1. Simple structure, wide applicability, small footprint and low noise.

2. Powdered feed and grass powder can be granulated without (or a little) liquid addition. Therefore, the moisture content of pelleted feed is basically the moisture content of the material before pelleting, which is more conducive to storage.

3. The particles made by this machine have high hardness, smooth surface and sufficient internal curing, which can improve the digestion and absorption of nutrients, and can kill general pathogenic microorganisms and parasites. It is suitable for raising rabbits, fish, ducks and experimental animals. The economic benefits that can be obtained compared to mixed powdered feeds.

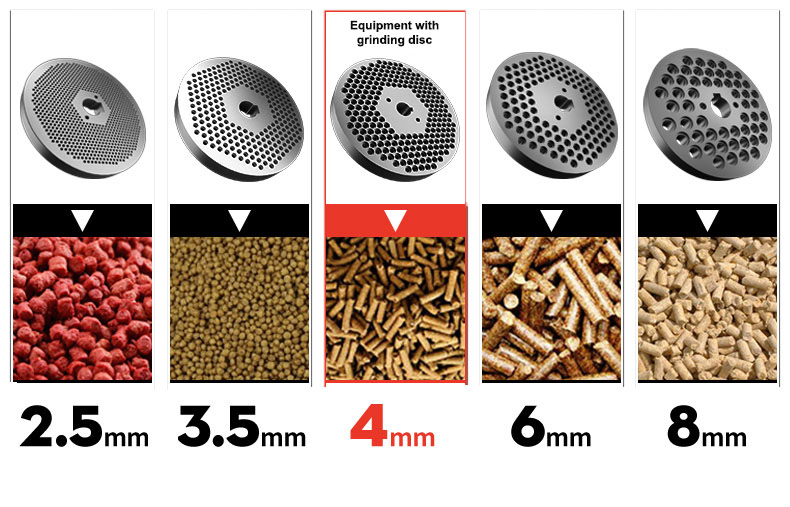

4. This model is equipped with 1.5-20 kinds of aperture molds, which are suitable for granulation of different materials and achieve the best effect.

5. Adapt to different materials to ensure the pressing effect. Compression molding of wood chips, corn stalks, etc. requires a lot of pressure. In the same kind of pelletizing equipment, the roller part is the central part of the whole equipment, and the alloy steel is used to improve the service life of the roller.

Specifications

| Model | Power(KW) | Yield(KG) | Rotating Sspeed | Dimensions(mm) | Weight |

| 120 | 3 | 40-50 | 320 | 1040*550*1140 | 68 |

| 150 | 4 | 75-125 | 320 | 1280*600*1250 | 92 |

| 210 | 11 | 200-250 | 320 | 1500*850*1400 | 189 |

| 260 | 15 | 350-500 | 380 | 1980*800*1600 | 300 |

| 300 | 18.5 | 500-800 | 380 | 2080*900*1750 | 410 |

| 400 | 37 | 1200-1500 | 400 | 2200*1200*1950 | 600 |

Instructions

1. The gearbox can be turned on after adding hyperbolic gear oil.

2. Install the pellet machine smoothly, check whether the steering meets the requirements, whether the screws in each part are loose, loosen the clearance adjustment screws on the roller axle seat, and make the feed machine in a no-load state, and it can be put into use after starting and running normally.

3. Before the new machine is used for the first time, take 10 catties of sawdust or grass powder vegetable oil or waste oil and mix it evenly, and then turn the clearance adjustment screw. Make the two rollers rotate at the same speed, gradually add the refueling feed, and at the same time continue to screw the adjusting screw of the pressing wheel until the material is slowly discharged, the extruded pellets are repeatedly squeezed to make the grinding hole smooth and smooth, and then the required mixed feed is processed. .

4. During feed processing, if there are more refined fibers, about 5% of water should be added. If there are too many concentrates in the mixed feed, the amount of water added can be reduced as appropriate. After processing, add a little oil that has been mixed with edible oil in advance. It is beneficial to start the machine next time and avoid the feed drying in the hole after the machine is stopped.

5. After processing, loosen the clearance adjustment screw to keep the roller in a free state. After the machine is stopped, remove the residual material accumulation in the upper and lower warehouses, especially the residual material at the bottom of the shaker to avoid damage to the bearing.

Our Factory

Our factory currently enjoys a robust position in the export market, with a notable surge in the demand for our equipment. The quality and reliability of our products have positioned us as a preferred choice for many consumers. Numerous individuals and businesses alike are opting for our offerings, recognizing the superior performance and durability that our equipment provides.

One of the key factors contributing to our success in the export market is the guarantee of manufacturing excellence that we uphold. Our factory has demonstrated unwavering commitment to producing top-tier products, backed by stringent quality control measures. This commitment not only ensures the satisfaction of our existing customers but also attracts new clients seeking reliable and high-performance equipment.

The strength of our manufacturer lies not only in the quality of our products but also in our ability to adapt to market trends and customer needs. We continuously invest in research and development to stay ahead of the curve, incorporating innovative features that set our equipment apart from the competition.

As a result of these factors, our factory is experiencing a notable upswing in exports, cementing our position as a leading player in the industry. The trust and confidence placed in our products by a growing customer base attest to the strength and credibility of our manufacturing processes. We are poised for continued success in the global market as we strive to exceed customer expectations and maintain the high standards that define our brand.

To become the stage of realizing dreams of our employees! To build a happier, a lot more united and more expert workforce! To reach a mutual profit of our buyers, suppliers, the society and ourselves for Factory Outlets Industry Rapid Mixer Granulator Machine, We believe that a passionate, revolutionary and well-trained team should be able to set up very good and mutually useful business relationships along with you soon. Remember to really feel no cost to get in touch with us for more facts.

Factory Outlets China Granulator Machine and Rapid Mixer Granulator Machine, Look forward to the future, we are going to focus more on the brand building and promotion . And in the process of our brand global strategic layout we welcome more and more partners join us, work together with us based on mutual benefit. Let’s develop market by fully utilizing our comprehensive advantages and strive for building.