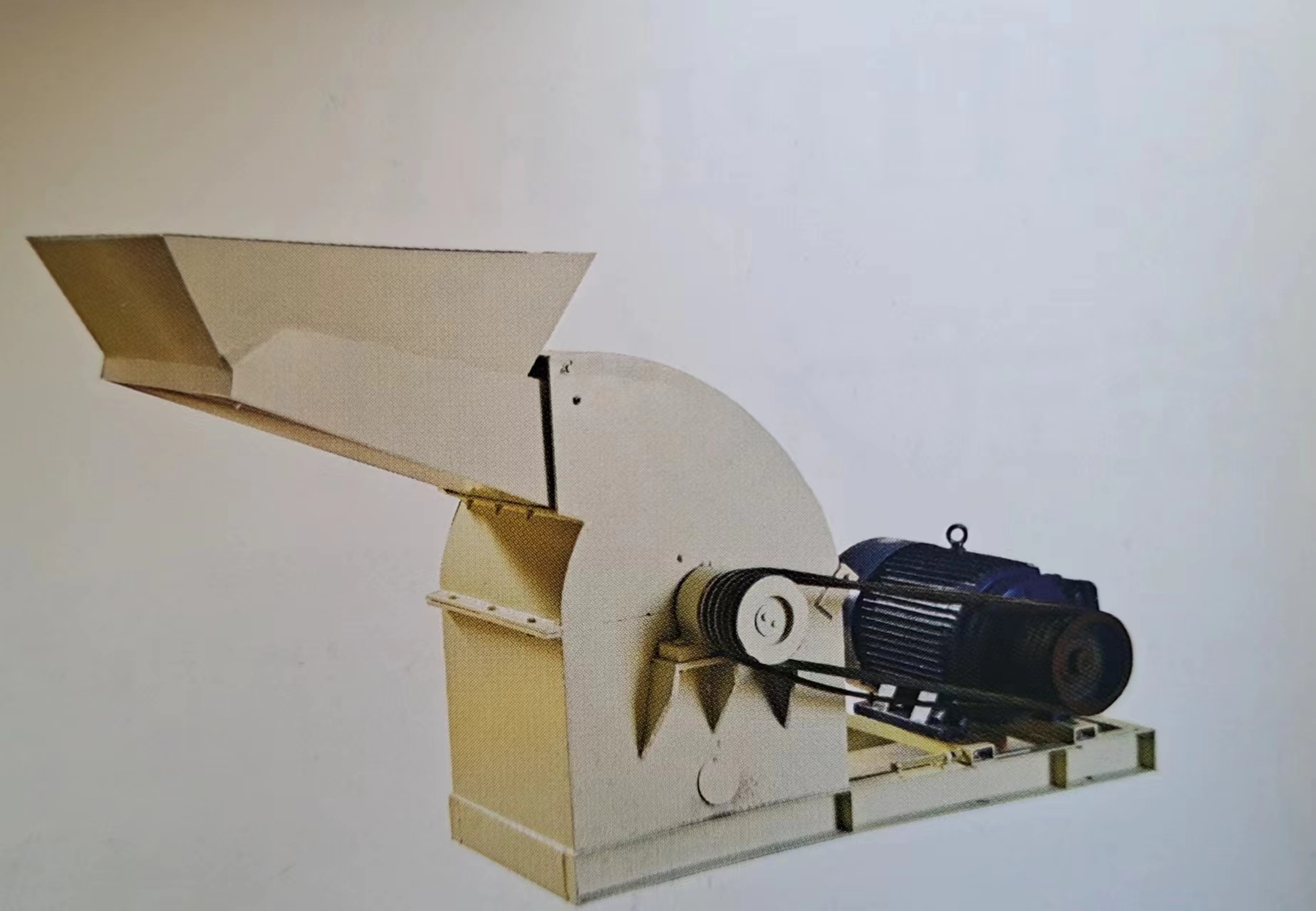

Hammer crusher solves your material crushing problems

| Applicable Industries | Manufacturing Plant, Construction works ,Energy & Mining, Other |

| Place of Origin | Hebei, China |

| Weight | 25000 KG |

| Warranty | 1 Year |

| Core components | motors, engines, bearings, others |

| Mechanical test report | Provide |

| Video outgoing inspection | Provide |

| Warranty of core components | 1 Year |

| Main selling point | High productivity |

| situation | brand new |

Product Description

Hammer mill is one of the important equipment in the biomass pellet production line. Hammer crusher can be used to crush corn stalks, straw, grass, sawdust, wood, branches and other waste. It adopts an internal cooling structure to avoid mechanical damage caused by high temperatures caused by friction. It has a reasonable structure, strong, durable, safe, reliable, easy to operate, small vibration, and high efficiency. Mainly used in lumber mills, feed mills, breeding plants, organic fertilizer plants, medicine, chemical and other industries.

Application areas

Livestock and poultry feed processing: Hammer crusher is an important equipment for processing feed. It can crush corn, soybeans, wheat bran and other crop materials into particles suitable for livestock and poultry consumption.

Crop Residue Disposal: After crop harvest, the disposal of crop residues is crucial for soil protection and reuse. Hammer crushers can crush these residues into fine particles to facilitate soil decomposition and recycling.

Biomass energy production: Biomass energy, such as sawdust, straw, etc., can be used for biomass energy production after crushing, such as biomass pellet fuel and biomass fuel power generation.

Hammer crusher features

High efficiency and energy saving: Hammer crusher can efficiently crush various raw materials, with low energy consumption and high production efficiency.

Versatility: Suitable for crushing a variety of raw materials and has a wide range of applications.

Maintenance cost: Although the hammer crusher performs well in the crushing process, its maintenance and upkeep are also crucial. The wear of blades, bearings and other components needs to be checked regularly to ensure the normal operation of the equipment.

| Model | Power(kw) | Capacity(t/h) | Hammer O t y | Dimensions(m) |

| 50-4 | 22 | 1 | 32 | 1.4×0.8×1.25 |

| 60-6 | 37+7.5 | 1-1.2 | 56 | 1.8×0.9×1.55 |

| 80-8 | 55+11 | 1.5-2 | 80 | 2.2×1.8×1.5 |

| 80-12 | 90+15/110+15 | 3-4 | 180 | 2.3×2.3×1.5 |

| 90-15 | 132+15 | 4-5 | 240 | 2.5×2.6×2.2 |

| Model | Power(kw) | Capacity(t/h) | Hammer O t y | Dimensions(m) | Weight(t) |

| YFCZ 40 | 7.5 | 0.2-0.5 | 12 | 1310×800×1070 | 0.27 |

| YFCZ 50 | 15 | 0.6-0.8 | 16 | 1380×800×1070 | 0.45 |

| YFCZ65×27 | 22 | 0.8-1.5 | 24 | 1500×1000×1100 | 1.1 |

| YFCZ 65×55 | 37-45 | 1-2 | 48 | 1700×1000×1100 | 1.7 |

| YFCZ 65×75 | 55-75 | 2-3 | 72 | 2100×1000×1100 | 2.2 |

| YFCZ 65×100 | 90-110 | 3-4 | 96 | 2400×1000×1100 | 2.6 |

| YFCZ 130×55 | 110-160 | 5-6 | 80 | 2800×1620×2100 | 5.6 |

| YFCZ 130×100 | 160-220 | 7-8 | 160 | 3020×1620×2170 | 7.1 |

Post time: Mar-11-2024

CN

CN