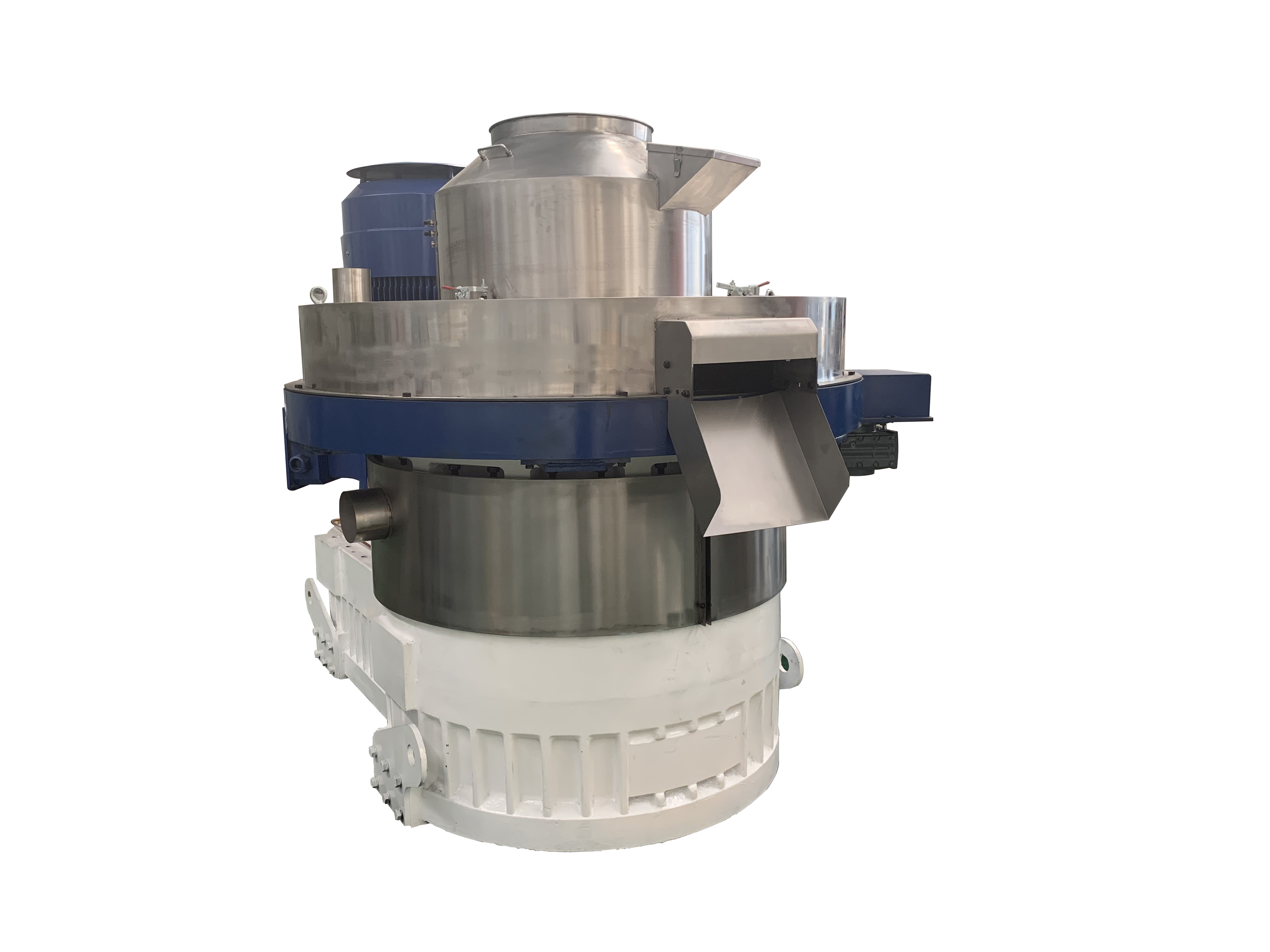

Pelletizer: Transformation from raw materials to finished products

Hebei Xingtang Huaicheng Machinery Equipment Co., Ltd.

Pellet mill, as a common processing equipment, plays a vital role in all walks of life. It can convert raw materials into granular finished products through a series of process steps, and is widely used in chemical industry, food, medicine and other fields.

Other properties

| Type | pellet machine |

| Applicable industries | farm, feed mill |

| Showroom location | not any |

| birthplace | Hebei china |

| Weight | 100kg |

| Warranty | 1 year |

| Main selling points | Easy to operate |

| Marketing Type | New products |

| Core component warranty | 1Year |

| Core Components | Gears, motors |

| Health condition | new |

| application | feedlot |

| Product name | Animal food processor Chicken and cat feed pellet machine |

| capacity | 500 kg/h |

| Usage | Animal poultry and livestock breeding |

| Color | Black/Blue/Customizable |

| Packaging details | Customized/wooden box/container |

Technical Parameters

| Model | Power(kw) | Pelletsize(mm) | inner dia (mm) |

Production (t/h) |

Dimension (mm) |

Weight (t) |

| YFK450 | 55 | Φ4-Φ12 | 450 | 0.3-1 | 2200×900×1600 | 3 |

| YFK550 | 75 | Φ4-Φ12 | 550 | 0.7-1 | 2300×1000×1780 | 5 |

| YFK560 | 90 | Φ4-Φ12 | 560 | 1-1.5 | 2600×1300×2300 | 6.3 |

| YFK680 | 160 | Φ4-Φ12 | 680 | 2-2.5 | 3200×1400×2400 | 8.5 |

| YFK850 | 220 | Φ4-Φ12 | 850 | 2-3 | 3750×1650×3250 | 12.6 |

| YFK880 | 315 | Φ4-Φ12 | 880 | 3-4 | 4300×1900×3600 | 14.5 |

Working principle

Raw material processing: First, the raw materials undergo preliminary processing, such as crushing, mixing, etc., to ensure that they are suitable for entering the granulator for the next step of processing.

Feeding and conveying: The processed raw materials are conveyed to the feed port of the pellet machine, usually through conveyor belts or screw conveyors and other equipment.

Granulation process: After the raw materials enter the pellet machine, they are squeezed, extruded or pressed through the rotating mold or roller, so that the raw materials form granular finished products. At the same time, the pressure, temperature and other parameters of the pellet machine can be adjusted according to different processing requirements.

Particle forming: After the formed particles undergo cooling, solidification and other processes, they are discharged from the discharge port of the pellet machine and undergo necessary packaging, storage and other processing.

Application scope

Chemical industry: Used to produce granular products such as fertilizers, plastics, and rubber.

Food processing: used to produce granular food raw materials such as grains, beans, feed, etc.

Pharmaceutical manufacturing: Used to prepare granular products such as drugs and pharmaceutical intermediates.

Agricultural field: Used to prepare granular agricultural products such as seeds, feed, and fertilizers.

Environmental protection industry: used to prepare granular biomass fuel, sludge treatment and other products.

Development trend of pellet machine

Intelligent technology: Introduce intelligent technology, such as sensors, automated control systems, etc., to improve production efficiency and product quality.

Green and environmentally friendly: Develop more environmentally friendly and energy-saving pellet machines to reduce energy consumption and environmental pollution.

Multifunctional design: Design a more flexible and diverse pellet machine that can adapt to the processing needs of different raw materials and realize the integration of multiple processing techniques.

As an important processing equipment, pellet mill has wide application prospects in all walks of life. With the continuous advancement of technology and changing market demands, pellet machines will continue to develop and improve, providing more reliable and efficient solutions for production in various industries.

Applicable scene

Company Profile

The company is located in Xingtang Economic Development Zone, Shijiazhuang, Hebei Province. The company has been committed to the research, design, development and manufacturing of various types of dust collectors, magnetic separators, vibrating screens, dryers, sand washers, conveyors, etc. Mining Equipment. The company adheres to the concept of “technology first, integrity first”.

Technical strength:

Huaicheng Machinery has an efficient team composed of experienced engineers and technical experts, constantly pursuing technological innovation and product upgrades. In terms of mechanical structure design and automated control systems, Huaicheng Machinery has always maintained a leading position in technology.

Manufacturing process:

Huaicheng Machinery has advanced production equipment and a strict quality control system to ensure that every piece of equipment can meet customer requirements. The company focuses on the refinement and standardization of production processes, using advanced processing techniques and sophisticated testing methods to ensure product stability and reliability.

Customer service:

Huaicheng Machinery always puts customer needs first and takes satisfying customer needs as its own responsibility.

Looking to the future:

As an enterprise that constantly pursues excellence, Huaicheng Machinery will continue to adhere to the purpose of “quality first, customer first”, continuously improve its technical strength and service levels, and provide customers with better industrial solutions. In the future, Huaicheng Machinery will continue to be committed to technological innovation and product upgrading, and work hand in hand with customers to create a better future together!

Hebei Huaicheng Machinery Equipment Co., Ltd. looks forward to working with you to create

brilliance together!

Post time: Mar-29-2024