Durable stainless steel livestock drinking trough

Durable stainless steel livestock drinking trough,

Durable stainless steel livestock sink Anti-rust stainless steel drinking trough for livestock Stainless steel trough, long service life, superior durability Industrial grade stainless steel livestock drinking trough Stainless steel trough designed for long-term drinking water for livestock High Durable Stainless Steel Livestock Sink, used for livestock drinking water Multifunctional stainless steel livestock sink Top stainless steel livestock drinking trough High quality stainless steel livestock drinking trough Stainless steel li,

Description details

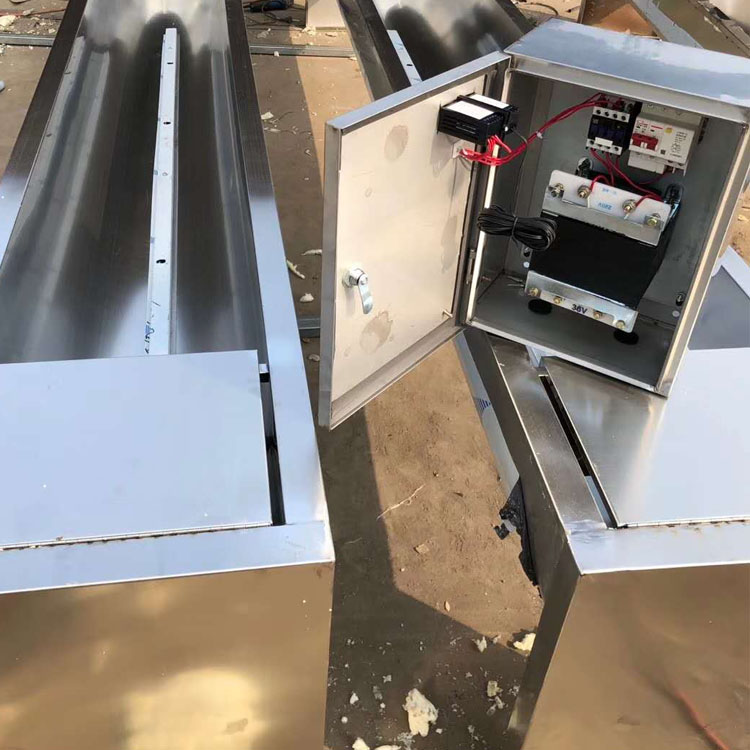

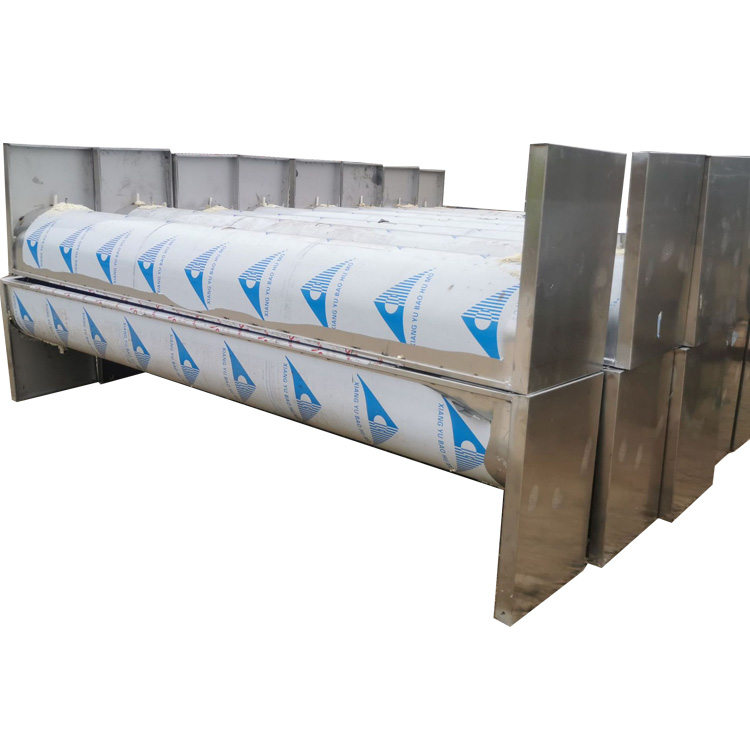

The drying furnace is mainly used in mineral processing, building materials, metallurgy, chemical industry and other departments to dry materials with a certain humidity or particle size. It is a commonly used mining machinery and equipment. The drying furnace is reliable in operation, flexible in operation, strong in adaptability, and large in processing capacity. The drying furnace can also be called a rotary drum drying furnace. Both ends of the drying furnace host are highly sealed, which is energy-saving and environmentally friendly.

The wet material is sent to the hopper by the belt conveyor or bucket elevator, and then enters the feeding end through the feeding pipe of the feeding machine of the hopper. The inclination of the feeding pipe should be greater than the natural inclination of the material so that the material can flow into the drying furnace smoothly. The cylinder of the drying furnace is a rotating cylinder that is slightly inclined to the horizontal line. Materials are fed from the higher end. The heat carrier enters from the lower end and contacts the material in countercurrent, and some heat carriers and materials flow into the cylinder together. With the rotation of the cylinder, the material moves to the lower end under the action of gravity. When the wet material moves forward in the barrel, it receives heat from the heat carrier directly or indirectly, so that the wet material can be dried, and then it is sent out at the discharge end through a belt conveyor or a screw conveyor. The inner wall of barrel is equipped with lifting flight, which can lift the materials and scatter them, increases contact surface of materials and airflow, in order to improve the drying speed and forward the materials advancement. The heat carrier is generally divided into hot air, flue gas, etc. After the heat carrier passes through the drying furnace, a cyclone dust collector is generally required to capture the material in the gas. If you need to further reduce the dust load of the end gas, it should pass through the bag filter or wet dust collector and then be released.

Drying furnace equipment has many advantages, its performance is stable and good, energy consumption is relatively low, and it can be used in a wide range. The drying area of the drying furnace is divided into several. Multiple drying areas not only increase the drying power, but also save energy and reduce consumption. In addition, the performance of the drying oven is much stronger than that of the traditional dryer, the performance is more stable, the operation is easier, and the drying time is shorter, which is why the drying oven is so widely used.

Example 1: After the coal in this coal factory is dried by the rotary drying furnace, the fly ash is absorbed by the dust collector, and the dried material is discharged from the lower outlet, and the dried product is transported to the designated position by the conveyor.

Example 2: This is the supporting facility of the sand factory. After the sand is washed by the sand washing machine, it is screened. However, the surface moisture of the material is very large, and it needs to be dried in a rotary drying furnace.

Our Factory

Introducing our latest innovation in the livestock industry – the durable stainless steel livestock drinking trough. This product is specifically designed to meet the needs of farmers and ensure an efficient water supply for their valuable livestock.

Introducing our latest innovation in the livestock industry – the durable stainless steel livestock drinking trough. This product is specifically designed to meet the needs of farmers and ensure an efficient water supply for their valuable livestock.

The main feature of our stainless steel drinking troughs is their durability. Constructed of high-quality stainless steel, this feed trough is able to withstand the toughest conditions on the farm. Whether it’s extreme weather or the occasional rough treatment of animals, our livestock drinking troughs will remain intact and functional for many years to come. This durability is a cost-effective investment for farmers, as they can rest assured that their gutters will not have to be replaced or repaired as often.

Plus, our stainless steel tanks are designed with hygiene in mind. We understand the importance of providing livestock with clean and safe drinking water as this directly affects their health and productivity. The stainless steel material not only resists bacterial growth, but is also easy to clean. Just wiping the trough with a cloth or rinsing it with water is enough to keep it hygienic. This prevents the build-up of bacteria and algae, ensuring a steady, clean water supply for the animals.

In addition to being durable and hygienic, our stainless steel drinking troughs also have a functional design. It is characterized by a large capacity that allows multiple animals to drink water at the same time. This saves farmers time and effort in replenishing water sources throughout the day. In addition, the trough is equipped with a high-quality float valve system to ensure a stable water supply for livestock. With this design, farmers can rest assured that their animals will always have access to fresh water when they need it.

Our stainless steel drinking troughs are incredibly versatile when it comes to installation. It can be easily mounted on a concrete wall or placed on the ground, depending on the farmer’s preferences and needs. The installation process is very simple and can be done with ease. This adaptability makes our troughs suitable for all types of livestock farming, including dairy farming, beef production, sheep and goat husbandry and more.

All in all, our durable stainless steel livestock water troughs offer farmers a long-lasting and cost-effective solution to providing clean water to their animals. Its high-quality construction ensures durability even in the harshest conditions, while its easy-to-clean design enhances the standard of excellence in hygiene. The tank has a large capacity and a reliable float valve system that guarantees a steady water supply for multiple animals at the same time. Its versatility and ease of installation make it suitable for a variety of livestock operations.

Invest in our stainless steel drinking troughs today and experience the benefits of efficient water supply for your livestock. Take steps to improve your farming practices and ensure animal well-being.