Maximize efficiency with ration feed preparation machines

Maximize efficiency with ration feed preparation machines,

Maximize efficiency with modern dosing machines Efficiency-enhancing ration feed preparation machine Improve ration preparation efficiency Improve efficiency through advanced ration feed preparation M,

Core Introduction

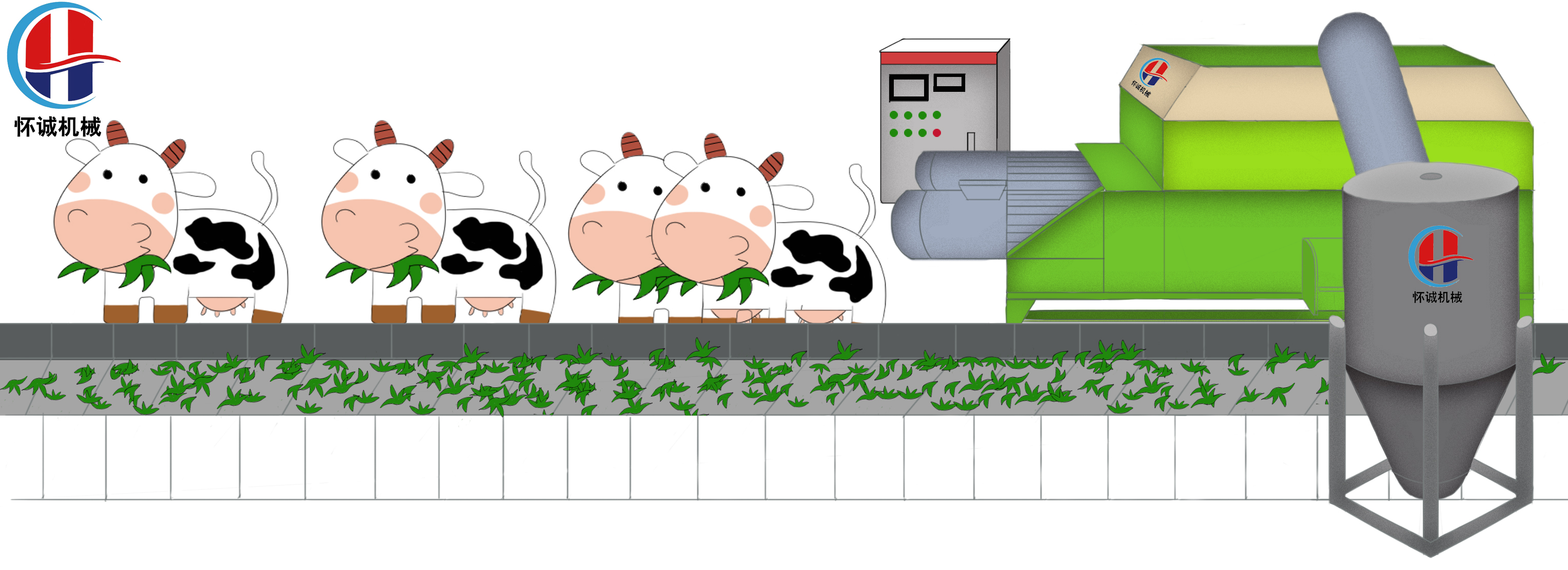

A Total Mixed Ration (TMR) is a mixture of forages, concentrates, minerals, microorganisms and other additives to provide enough nutrients to meet dairy cows’ needs. On the basis of supporting technical measures and TMR machinery with excellent performance, TMR feeding technology can ensure that every ration eaten by dairy cows is a full-price diet with stable concentration of concentrate and coarseness and consistent nutrient concentration, which is a major change in the way of feeding dairy cows. . The vertical feed mixer adopts a large screw auger, the feed is soft and palatable after mixing; the feed is not easy to agglomerate; due to the slow rotation speed of the auger, the damage to the fiber structure of the feed is small. The feed mixed by the stand mixer is soft and palatable, which will enhance the cow’s appetite and facilitate digestion. The feed mixed by the stand mixer is not easy to agglomerate. Agglomeration refers to the formation of dry and hard lumps due to excessive extrusion of the feed. The cows will always feel full after eating this kind of feed, and they cannot eat too much. Since the horizontal structure of the auger is horizontal, it is easy to over-squeeze the feed, but this is not the case with the vertical mixer. Due to the slow rotation speed of the auger, the vertical mixer has little damage to the fiber structure of the feed. Once the fiber structure is damaged, nutrients are quickly lost. Stand mixers maintain feed nutrients for a longer period of time. .The mixing tank has less wear and longer service life; with automatic weighing device, the addition amount can be set at any time.

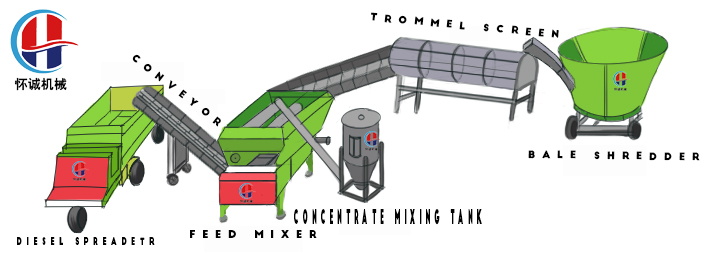

How can one person feed 500 cows? This was impossible ten years ago. With the development of the times and the advancement of science and technology, feeding 500 cows by one person has become an achievable task. The use of mechanized feeding, reclaiming, stirring, and feeding is completed by one person, and the mechanical equipment goes to the silage tank to reclaim the material, and the silage reclaimer is used to complete it by one person. The feed is taken to the spreader, and the spreader is driven to the tmr feed mixer. The mixing is also completed by one person. The mixed feed is transported to the spreader through the belt conveyor, and then driven to the cattle farm for automatic feeding. The whole process is completed by one person. If you are not sure what equipment is suitable for you, please contact the customer service staff to inform your needs, we can design a plan for you according to the scale of your breeding plant.

Show details:

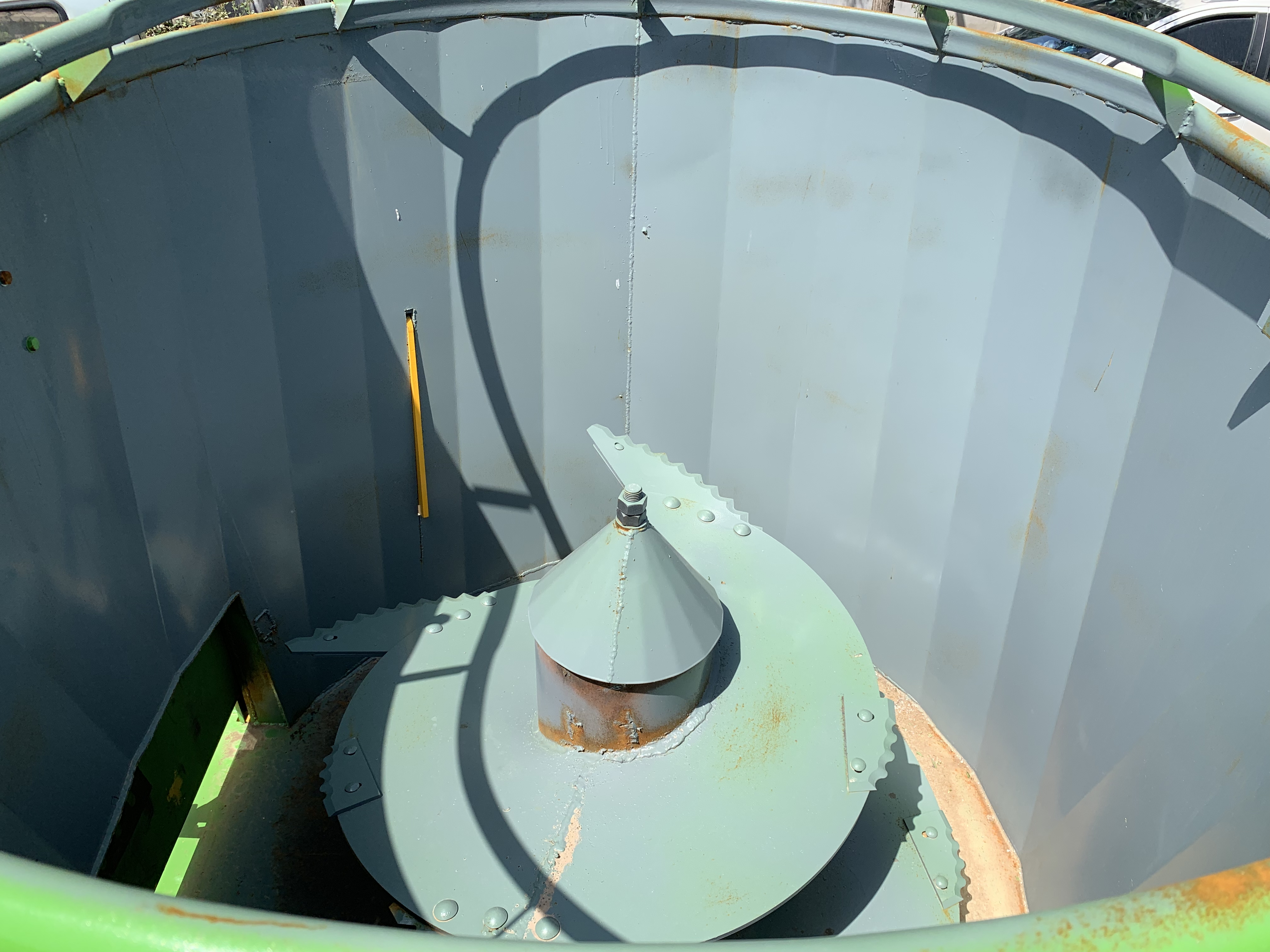

Huge auger with manganese steel blade attached.

Accurate weighing system for scientific proportioning.

Hydraulic operating lever to control the size of the discharge port.

Independent oil pot, safe and convenient.

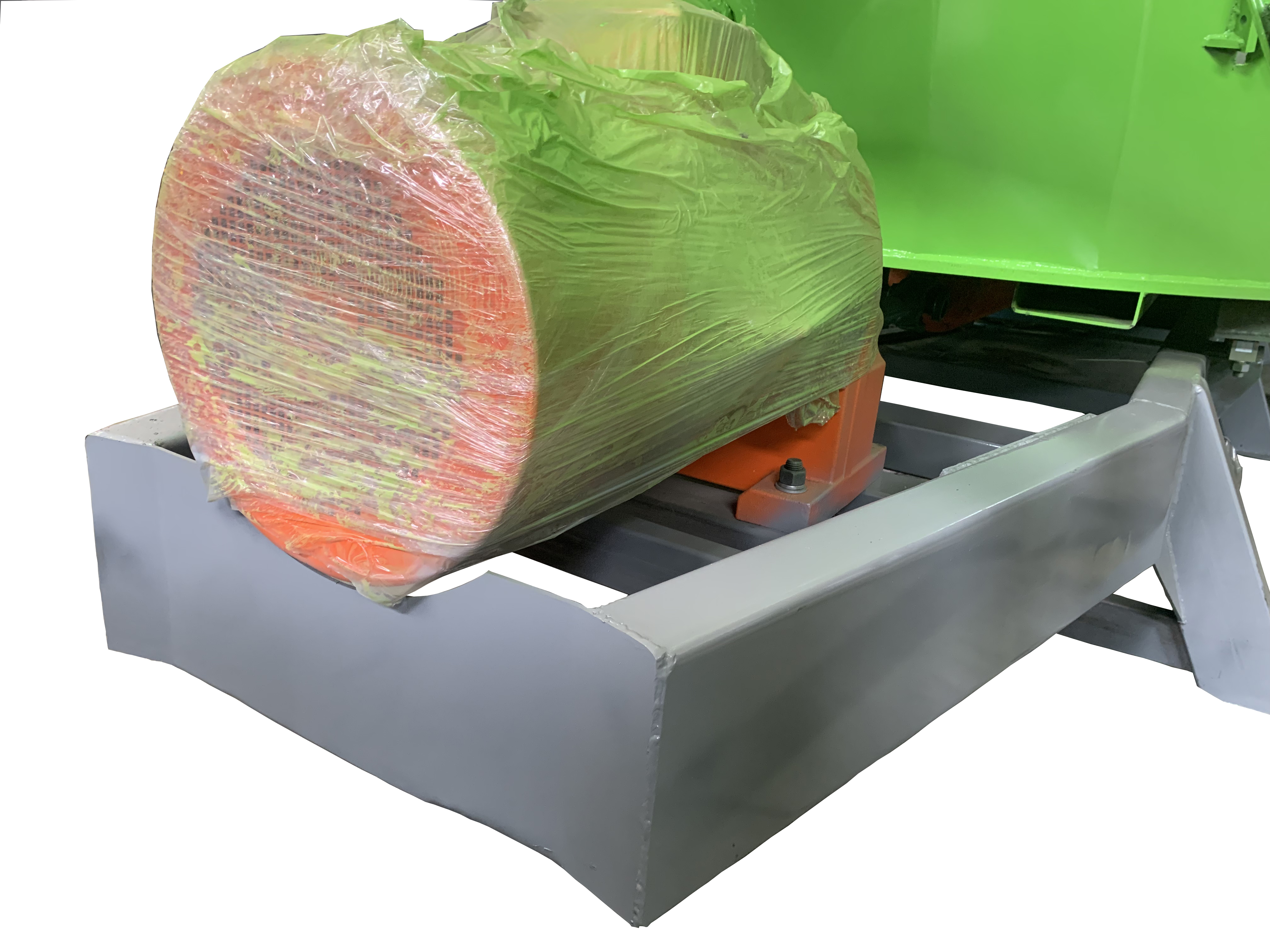

Pure copper national standard motor.

Three-phase electricity provides power.

Mechanized farming case display:

Vertical Mixer vs. Horizontal Mixer: Understanding the Key Differences Design Orientation: Vertical mixers are designed with a vertical axis, where the mixing chamber is positioned vertically, while horizontal mixers have a horizontal axis, with the mixing chamber positioned horizontally. Mixing Action: Vertical mixers employ a gravity-based mixing action, where the ingredients are pulled downwards by gravity and then lifted up again by the mixing auger. In contrast, horizontal mixers use an aggressive horizontal mixing action, where the ingredients are rapidly and forcefully mixed together. Mixing Efficiency: Vertical mixers are generally more efficient at thoroughly blending ingredients due to the gravity-based mixing action, which allows for better ingredient distribution. Horizontal mixers, on the other hand, can be more efficient at achieving a faster mixing time, especially for larger volumes of feed. Mixing Capacities: Vertical mixers are often more suitable for small to medium-sized livestock operations, as they typically have lower mixing capacities compared to horizontal mixers. Horizontal mixers, with their larger mixing capacities, are better suited for larger-scale livestock operations or feed production facilities. Ingredient Versatility: Vertical mixers are generally better suited for handling a wide variety of dry and wet ingredients, including fibrous materials. They can handle both long-cut and short-cut forages effectively. Horizontal mixers, while still versatile, may require additional features or modifications to handle certain types of ingredients, especially fibrous materials. Space Requirements: Vertical mixers tend to have a smaller footprint compared to horizontal mixers, making them more space-efficient, which can be advantageous for farms or facilities with limited space. Unloading Methods: Vertical mixers typically unload from the bottom, utilizing gravity to discharge the mixed feed into a feeding trough or conveyor system. Horizontal mixers may offer various unloading methods, including side discharge, rear discharge, or bottom discharge, depending on the specific model. Cost Considerations: Vertical mixers are often more affordable and cost-effective compared to horizontal mixers, making them a popular choice for smaller livestock operations or those with budget constraints. Horizontal mixers, with their larger capacities and more complex designs, tend to be more expensive. Maintenance and Cleaning: Vertical mixers generally have simpler designs and fewer moving parts, making them easier to maintain and clean. Horizontal mixers, with their more complex mechanisms and larger size, may require more frequent maintenance and can be more time-consuming to clean thoroughly. Operator Convenience: Vertical mixers often offer easier access to the mixing chamber for ingredient loading, monitoring, and adjustment. Horizontal mixers may require more effort for ingredient loading, especially for larger models, and may have limited visibility during the mixing process. Understanding these key differences between vertical and horizontal mixers can help you make an informed decision when choosing the most suitable mixer for your specific livestock operation or feed production needs.

Our Factory

Introducing our state-of-the-art ration feed preparation machines, designed to maximize efficiency and revolutionize the way you manage your livestock farm. With these machines, you can finally say goodbye to the hassle of manual preparation and tedious mixing processes.

Our ration feed preparation machines are equipped with advanced technology and a user-friendly interface, ensuring seamless operation and consistent results. Whether you are a small-scale farmer or managing a large agricultural business, our machines can meet the needs of farms of all sizes.

One of the key features of our dosing feed preparation machines is the ability to precisely mix ingredients in the required ratios to ensure optimal nutrition for your animals. This level of accuracy is critical to help prevent undernutrition or overfeeding, thereby improving herd health and productivity.

Our machines also feature built-in scales that allow you to measure the exact amount of each ingredient. This eliminates the need for manual measurements, reducing the chance for error and ensuring consistent recipes across batches.

In addition to efficiency and accuracy, our ration feed preparation machines are designed with ease of use in mind. An intuitive interface and automated processes make it easy for anyone, regardless of experience level. Not only does this save you time, but it also eliminates the need for extensive training or additional staff.

Additionally, our machines are equipped with safety features to ensure the well-being of animals and operators. With built-in sensors and alarms, any abnormality or failure can be detected immediately, allowing timely maintenance and preventing potential accidents.

By automating the feed preparation process, our machines also help to save a lot of time and labor. By reducing physical labor, you and your staff can focus on other farm tasks, increasing overall productivity and efficiency. Not only does this allow you to reallocate resources, but it also improves your team’s work-life balance.

Furthermore, our ration feed preparation machines are designed to be cost-effective which ultimately contributes to your bottom line. By optimizing raw material use, reducing waste and preventing costly mistakes, you can save on feed costs and increase your profit margin.

Investing in our ration feed preparation machines is a wise decision that will benefit your farm in several ways. Enjoy greater efficiency, improved herd health and significant cost savings while eliminating the stress and labor associated with manual mixing.

More and more farmers have experienced the transformative power of our machines. Discover the unparalleled convenience, accuracy and productivity offered by our ration feed preparation machines. Experience the future of livestock farming today – maximize efficiency and take your farm to new heights with our cutting edge machines.