High Performance Feed Preparation Machines

High Performance Feed Preparation Machines,

High performance feed preparation machine High performance feed preparation machine Advanced feed processing equipment Top feed preparation machine Efficient feed preparation machine Cutting edge feed,

Core Introduction

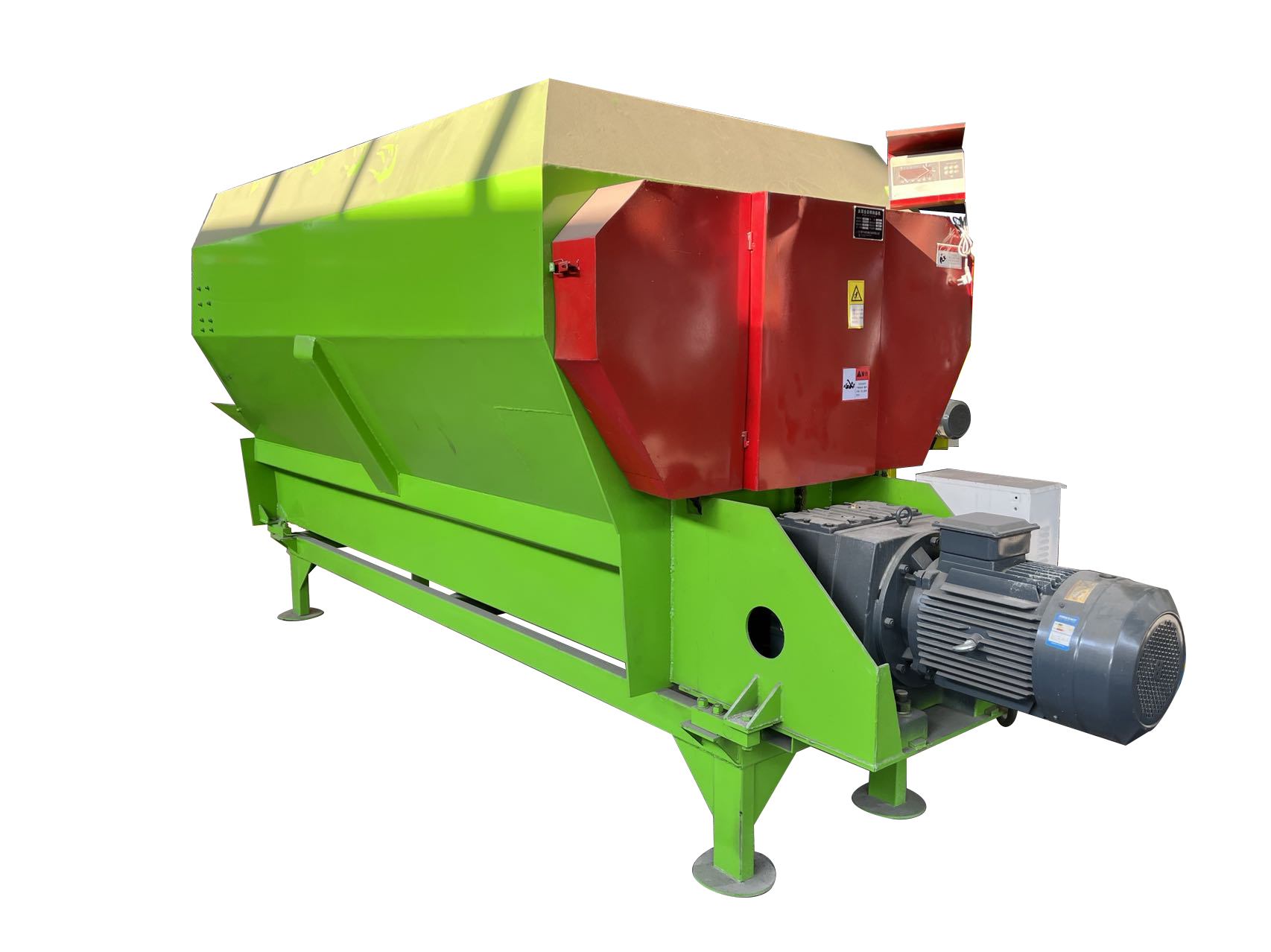

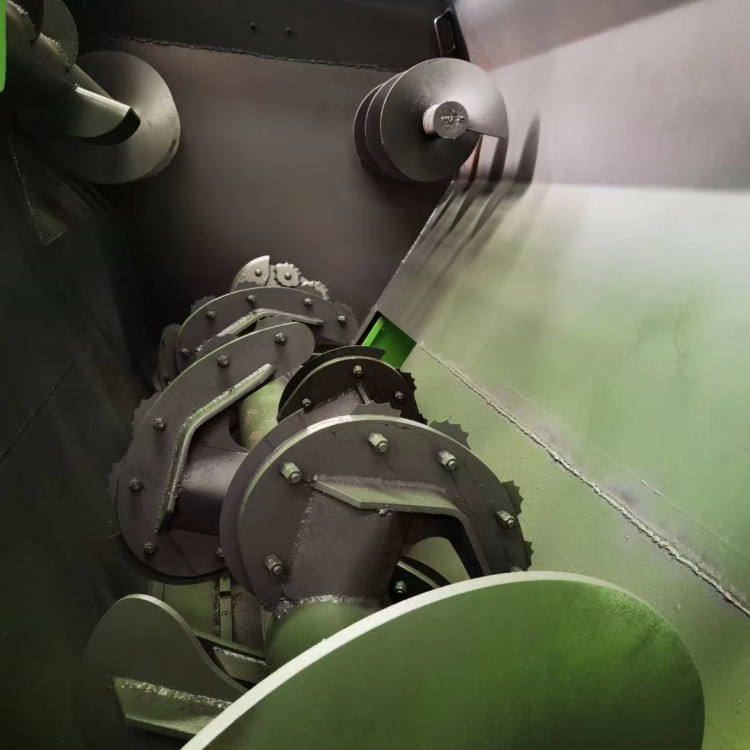

The total mixed ration mixer is mainly composed of one or two augers, and the spiral auger is divided into left-handed and right-handed. During mixing, cutting and stirring, the materials are rotated and stirred from all directions at both ends of the box to the middle of the mixer at the same time. Each helical lead on the screw body of the auger is equipped with a moving blade, which is used for cutting work with the fixed teeth on the center line of the feed mixer, cutting and stirring all kinds of fibrous forages and straws that pass through, so as to achieve full mixing with uniform pulverization and mixing. Dietary feeding effect.

TMR is the abbreviation of Total mixed rations in English. The TMR total mixed ration preparation machine is a feed processing equipment that integrates crushing, stirring and mixing. It can cut long grass, silage and other forages. Kneading silk, and can fully mix a coarse material, concentrate, minerals, microorganisms and other additives, can provide enough nutrition to meet the needs of dairy cows. On the basis of supporting technical measures and TMR machinery with excellent performance, TMR feeding technology can ensure that every ration eaten by dairy cows is a full-price diet with stable concentration of concentrate and coarseness and consistent nutrient concentration, which is a major change in the way of feeding dairy cows.

Compared with traditional feeding methods, TMR feeding has the following advantages: increasing the dry matter intake of dairy cows can eliminate the selectivity (picky eating) of dairy cows to a particular feed, which is conducive to maximizing the use of low-cost feed formulations . At the same time, TMR is completely mixed according to the proportion specified in the diet, which reduces the occasional lack or poisoning of trace elements and vitamins; improves milk quality; reduces the incidence of dairy cattle diseases; labor time, improve economic efficiency.

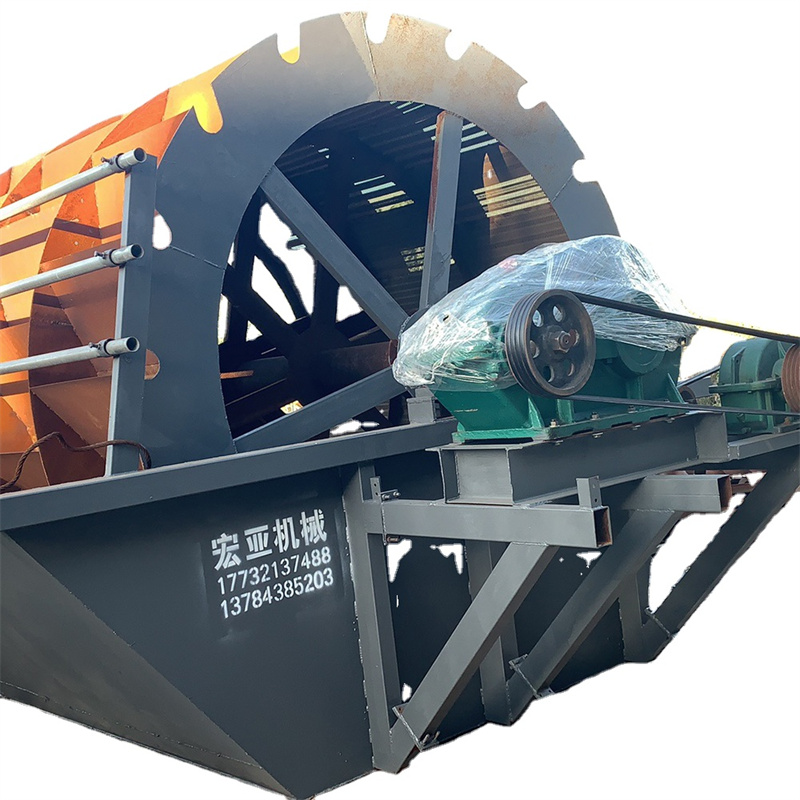

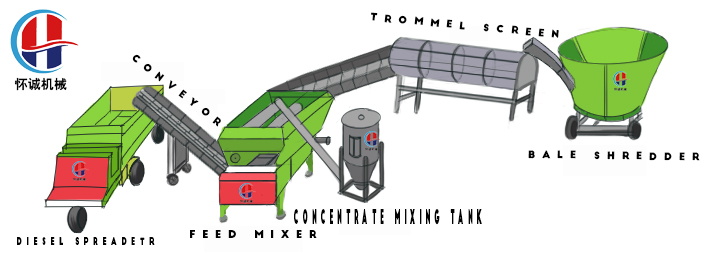

Mechanized farming case display:

After the automatic distribution box is opened, you can set the mixing time of the mixer, or set the default time, click Start, the mixer starts, the mixing starts to run, the grass enters the silo through the conveyor, the flour mill, and the fine material tank are opened simultaneously. After the fine material is mixed, it will automatically start feeding in the mixer. When the mixer is finished mixing, the hydraulic lifting door will automatically open and start discharging. At this time, the conveyor will automatically open and start running. The total length is 97 meters. After the material is discharged, the conveyor will stop running, and the bin door will be automatically closed. According to the degree of mixing of the grass, the reasonable mixing time can be appropriately modified and saved. When it is used next time, directly according to the Set the content and start with one key. The breeding system is our company in After the on-site inspection of the customer’s breeding factory, it was designed according to the customer’s requirements. The whole process of feeding cattle and sheep is automated, and the original drinking trough is replaced by a conveyor. It is also equipped with a water pump for water supply, a spray tower disinfection tank, cooling and disinfection, and a manure scraper. Carry out excrement cleaning work, save labor, and one person can feed hundreds of cows.

Show more details

1. Safety distribution box: support one-button start, button operation, providing safety guarantee for the whole machine

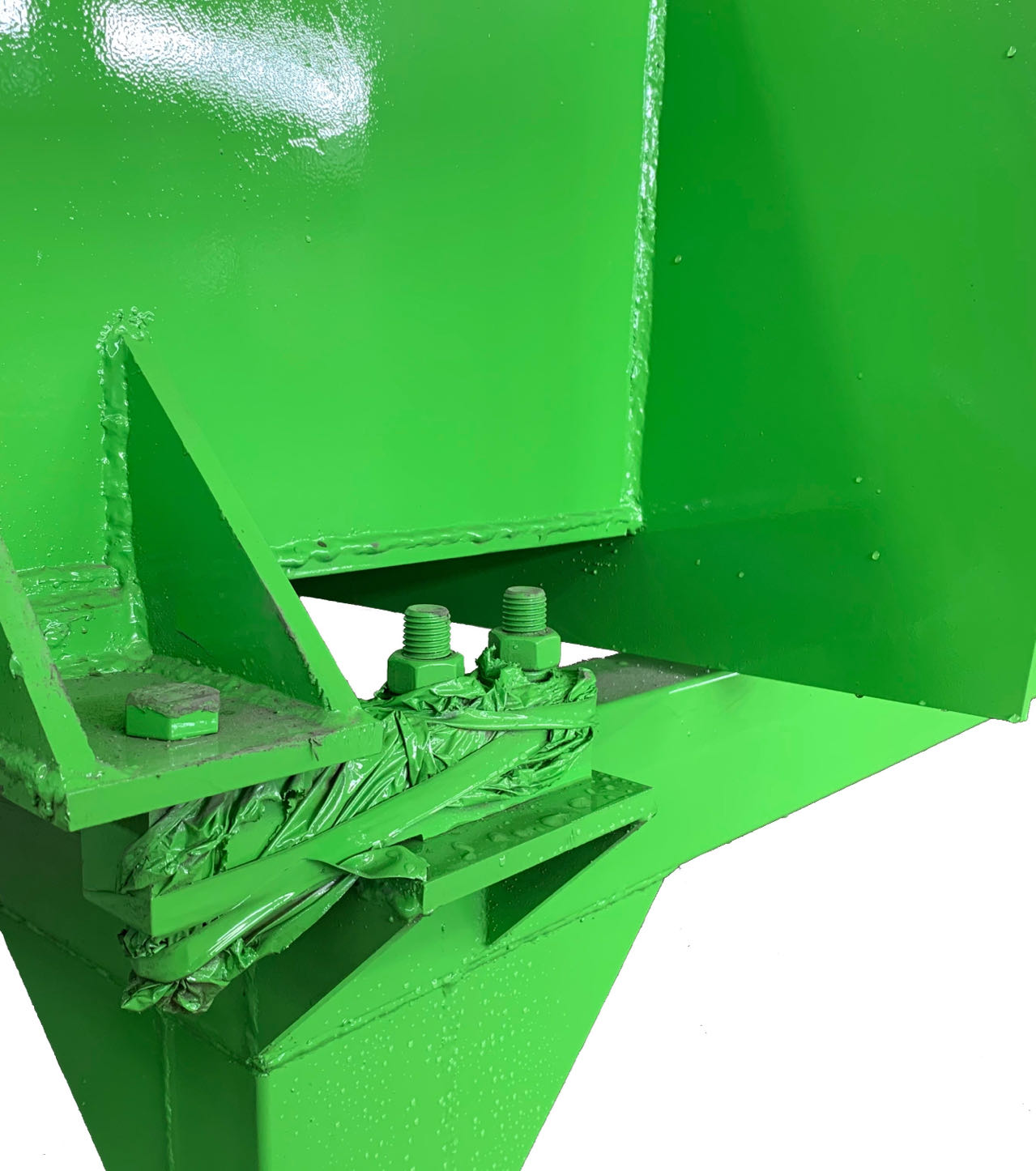

2. Independent hydraulic lifting system: independent oil pump drives a small handle to control the speed of the hydraulic grass outlet

3. Electronic weighing sensor: 8 tons of high-precision electronic weighing sensor can accurately calculate the ratio of concentrate and forage to realize scientific farming

Advantages

1. The concentrated roughage is evenly mixed to improve the palatability of the feed and avoid the occurrence of picky eating and nutritional imbalance in dairy cows;

2. It is beneficial to the synthesis of carbohydrates and carbohydrates, and to improve the utilization rate of protein;

3. Enhance rumen function, maintain the stability of rumen pH value, and prevent rumen acidosis;

4. It can maximize the dry matter intake of dairy cows and improve the conversion rate of feed;

5. According to the quality and price of roughage, flexibly adjust and effectively utilize non-roughage;

6. Reduce labor, improve breeding efficiency, and make animal feeding management more accurate;

7. It can make full use of local raw material resources to reduce the cost of feed;

8. It is beneficial to the large-scale production of cattle farms;

9. Conducive to epidemic prevention of dairy farms and reduce the incidence of diseases.

Our Factory

Introducing a High Performance Feed Preparation Machine – Revolutionizing Agricultural Productivity

In the fast-paced agricultural world, efficiency and productivity are of the utmost importance. Farmers and livestock producers face the constant challenge of maximizing yields while ensuring product quality remains unrivaled. This is where high-performance feed preparation machines come into play, changing the way feed is prepared and revolutionizing farming.

Our high-performance feed preparation machines are designed to optimize the production of nutritionally balanced feed for livestock. These machines are engineered with cutting-edge technology to deliver industry-leading performance and efficiency. With their advanced features, they simplify feed preparation, saving farmers valuable time and resources.

One of the main highlights of our high-performance feed preparation machines is their unrivaled versatility. Whether you raise poultry, cattle, pigs or any other type of livestock, our machines can meet your needs. From grinding and blending to blending and pelleting, these machines provide a comprehensive solution for all your feed preparation needs. With customizable settings, farmers can easily adjust the machine to meet the specific dietary requirements of their animals.

Our machines are not only efficient, but also increase the nutritional value of the feed. They are equipped with state-of-the-art technology that ensures a consistent particle size distribution, which improves digestibility in animals. These machines precisely blend ingredients such as grains, proteins, vitamins and minerals. By using our high-performance feed preparation machines, farmers can rest easy knowing their animals are getting the optimal combination of nutrients for better growth and performance.

In addition to technical advantages, our high-performance feed preparation machines prioritize operator safety and ease of use. With intuitive controls and a user-friendly interface, farmers can easily operate and monitor the machine, reducing the risk of accidents and errors. These machines are also designed with robust safety features to ensure the health of the operator and prevent any potential damage to the equipment.

Investing in our high-performance feed preparation machines can bring huge benefits to farmers and livestock producers. By increasing the overall efficiency of feed preparation, these machines can significantly reduce labor costs, allowing farmers to allocate resources to other important aspects of their operations. Furthermore, the consistent quality of the feed produced by our machines results in healthier and more productive livestock which ultimately increases the profit of the farmer.

We take pride in providing innovative and reliable agricultural solutions to our customers. With our state-of-the-art high-performance feed preparation machines, we are committed to supporting farmers in their goals of sustainable and profitable farming. Our machines are built to last and we have an unwavering commitment to excellent customer service and ongoing support.

Join the feed preparation revolution and take your agricultural productivity to unprecedented levels. Invest in high-performance feed preparation machines today and experience the transformative power they can bring to your farming operation. Together, let’s propel the agriculture industry into a new era of efficiency, nutrition and success.