Precision Nutrition: Unleashing the Potential of Feed Mixing Tanks

Feed Mixing Tank: Machine for Preparing High-Quality Feed

Xingtang Huaicheng Machinery Equipment Co., Ltd.  CN

CN

In modern livestock and poultry breeding, the quality of feed is directly related to the growth, development, health and production efficiency of animals. As a key piece of equipment, the feed mixing tank plays an important role in preparing high-quality feed.

Technical Parameters

| Type | Dimensions(L*W*H) | Production(t/h) |

| SLHL-500 | 1450*1450*2650mm | 1t/h |

| SLHL-1000 | 2700*1700*2650mm | 1.5t/h |

| SLHL-2000 | 2700*1700*3300mm | 2.5t/h |

Feed mixing tank function:The feed mixing tank is mainly used to mix various feed raw materials evenly in a certain proportion to prepare high-quality feed that meets the nutritional needs of animals

Mixing of raw materials: Put different types of feed raw materials, such as grains, soybean meal, fish meal, vitamins, etc., into the mixing tank according to the formula ratio and mix them to ensure the even distribution of various nutrients.

Adjust the feed ratio: Flexibly adjust the feed ratio according to the growth stages, breed characteristics and feeding goals of different animals to meet their nutritional needs.

Working principle:The feed mixing tank mixes the feed raw materials thoroughly and evenly through the stirring device

Feeding: Put various feed ingredients into the mixing tank according to the preset formula ratio.

Stirring: Start the stirring device in the mixing tank to evenly mix the input feed ingredients. During the mixing process, the feed ingredients are fully mixed through reasonably designed mixing structure and speed.

Discharge: After mixing is completed, the mixed feed is discharged from the mixing tank for subsequent processing or direct feeding to animals.

Feed mixing tank advantages

Improve feed quality: Through the mixing effect of the mixing tank, various feed raw materials are fully mixed, ensuring the balanced nutrition of the feed and improving the quality of the feed.

Cost savings: By accurately formulating feed proportions and fully mixing, feed waste can be reduced, feed costs can be reduced, and breeding efficiency can be improved.

Increase production efficiency: The automated operation of the feed mixing tank and efficient mixing system can greatly improve the efficiency of feed production, reduce manual labor, and increase production capacity.

Guarantee animal health: Nutritionally balanced feed helps ensure animal health, reduce disease rates, and increase breeding output.

As a key equipment in breeding production, the feed mixing tank plays a vital role in preparing high-quality feed, improving production efficiency and reducing costs. In future breeding production, feed mixing tanks will continue to play an important role and contribute to the development of the breeding industry.

Company Profile

The company is located in Xingtang Economic Development Zone, Shijiazhuang, Hebei Province. The company has been committed to the research, design, development and manufacturing of various types of dust collectors, magnetic separators, vibrating screens, dryers, sand washers, conveyors, etc. Mining Equipment. The company adheres to the concept of "technology first, integrity first".

Technical strength:

Huaicheng Machinery has an efficient team composed of experienced engineers and technical experts, constantly pursuing technological innovation and product upgrades. In terms of mechanical structure design and automated control systems, Huaicheng Machinery has always maintained a leading position in technology.

Manufacturing process:

Huaicheng Machinery has advanced production equipment and a strict quality control system to ensure that every piece of equipment can meet customer requirements. The company focuses on the refinement and standardization of production processes, using advanced processing techniques and sophisticated testing methods to ensure product stability and reliability.

Customer service:

Huaicheng Machinery always puts customer needs first and takes satisfying customer needs as its own responsibility.

Looking to the future:

As an enterprise that constantly pursues excellence, Huaicheng Machinery will continue to adhere to the purpose of "quality first, customer first", continuously improve its technical strength and service levels, and provide customers with better industrial solutions. In the future, Huaicheng Machinery will continue to be committed to technological innovation and product upgrading, and work hand in hand with customers to create a better future together!

Hebei Huaicheng Machinery Equipment Co., Ltd. looks forward to working with you to create brilliance together!

Company Profile

Customer Visit

Overseas Delivery

Exhibition

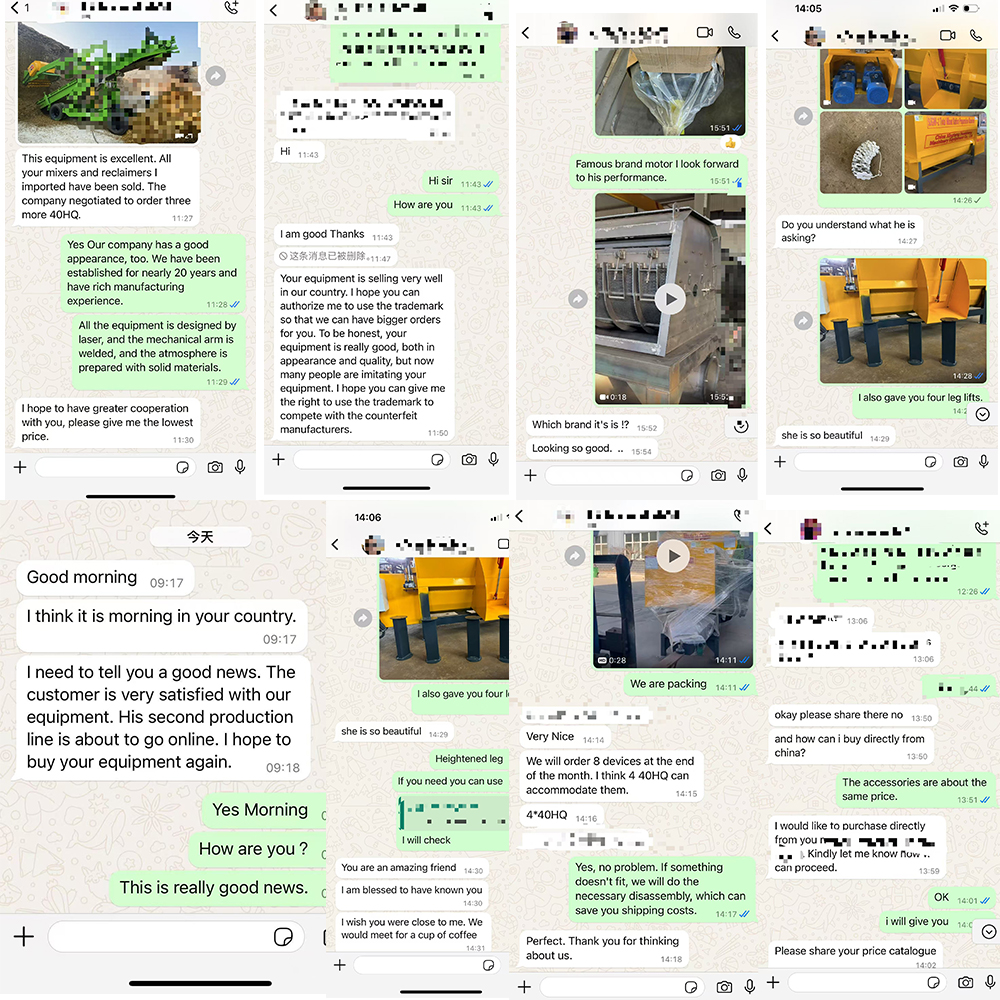

Feedback

![[Copy] Stay Ahead of the Competition and Transform Your Operations with the Efficiency of Our Advanced Screw Conveyor Technology](https://cdn.globalso.com/hcjxchinamachine/Efficiency-Redefined-Introducing-the-Next-Generation-of-Screw-Conveyors.jpg)