“Maximizing Efficiency with a Custom Grain Feeding Conveyor”

“Maximizing Efficiency with a Custom Grain Feeding Conveyor”,

Customized conveyor design Conveyor system integration Grain processing equipment Vertical conveying system Conveyor system automation Advanced grain processing technology Agricultural machinery manuf,

Basic Information

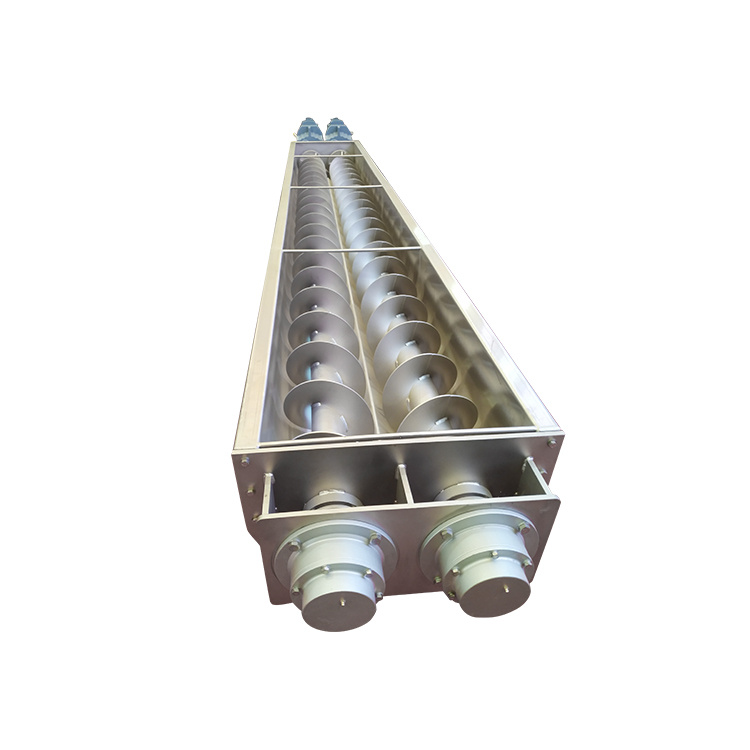

The belt conveyor is mainly composed of a frame, a conveyor belt, a belt roller, a tensioning device, a transmission device, etc. The fuselage is connected by high-quality steel plates, and the frame is formed by the height difference between the front and rear outriggers, and the plane is inclined at a certain angle. The frame is equipped with belt rollers, idlers, etc. to drive and support the conveyor belt. There are two ways of geared motor drive and electric drum drive.

In addition to belt conveyors, we also have screw conveyors, special-shaped conveyors, etc. for customers to choose, which are popular because of their simple operation, low price and many advantages.

Product Advantages

1. Low operating cost and stable performance.

High productivity, all of which are conducive to reducing production costs. Reliable operation, in many important production units that require continuous operation, it can work continuously one after the other. Low power consumption, because there is almost no relative movement between the material and the conveyor belt, not only the running resistance is small, but also the wear and breaking of the load are small.

2. Strong adaptability and diverse choices.

According to the requirements of the technological process, the belt conveyor can flexibly receive materials from one or more points, and can also discharge materials to multiple points or several sections. When feeding material to the conveyor belt at several points at the same time (such as the conveyor under the coal bunker in the coal preparation plant) or feeding the conveyor belt through uniform feeding equipment at any point along the length of the belt conveyor, the belt conveyor The machine becomes a main conveying trunk line. The transmission line has strong adaptability and flexibility. The length of the line is determined according to the needs. It can be as short as a few meters and as long as more than 10km. It can be installed in small tunnels, and can also be erected over areas with chaotic and dangerous ground traffic.

3. Reduce the difficulty and have high versatility.

The belt conveyor can take material in the tunnel below the coal storage yard, and can also mix different materials from each pile when needed. Material can simply be unloaded from the conveyor head.

Our Factory

introduce:

Maximizing efficiency is a key goal of most businesses. Whether you’re in agriculture or manufacturing, finding ways to save time and money while increasing production is critical. One area that can have a big impact on efficiency is your grain feeding system. With the right conveyor, you can simplify operations and get more done in less time.

Product Description:

Our custom grain feeding conveyors are designed to meet the specific needs of your business. Whether you need to transport grain from one location to another or load it into a processing machine, our conveyors can help. Here’s how it works:

– Flexible Design: Our conveyors can be customized to meet your unique requirements. We can design it to handle different types of grains, accommodate different yields, and fit into your existing workflow.

– Large capacity: Our conveyors are designed to move large quantities of grain quickly. Whether you need to fill a truck, silo or processing machine, our conveyors can do the job.

– Smooth Operation: Our conveyors are designed to run smoothly and quietly, minimizing downtime and reducing maintenance costs. We use high-quality materials and components to ensure your conveyors perform reliably, day in and day out.

– EASY INSTALLATION: Our conveyors are designed for quick and easy installation. We can provide everything you need to get your conveyor up and running, including installation instructions and the support of our expert team.

– Cost-effective: By simplifying your grain feeding system with our conveyors, you can save time and money. Designed for maximum efficiency, our conveyors can help you increase production and reduce labor costs.

Whether you are replacing an existing conveyor or need a new grain feeding system, we can help. Our team of experts will work with you to design a conveyor that meets your specific needs and fits your budget. With our custom conveyors, you can maximize efficiency and get more done in less time.