Mobile Belt Conveyor / Screw Conveyor Transport

Basic Information

Conveyors: the smart assistant for modern industrial production

Hebei Xingtang Huaicheng Machinery Equipment Co., Ltd.

In industrial production, the conveyor is a widely used automation equipment that realizes the automation and efficiency of the production process by transporting materials.

Types of

Belt conveyor: Belt conveyor is a kind of conveying equipment that uses belts as transmission carriers. It is suitable for transporting long distances and large quantities of materials. It is often used in mines, ports and other places.

Roller conveyor: Roller conveyor uses rollers to transfer materials. It is suitable for short-distance transportation of heavy materials and is often used in warehousing, logistics and other fields.

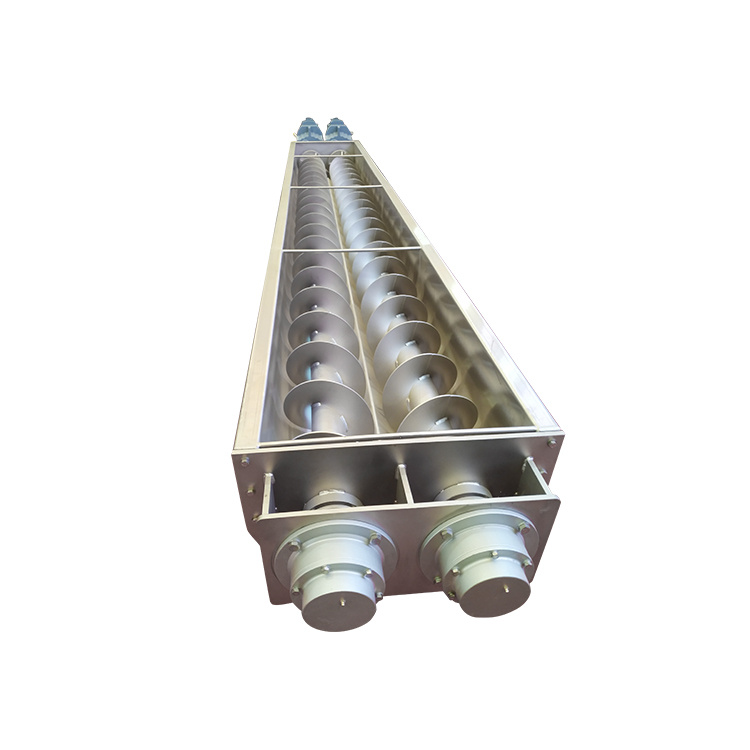

Screw conveyor: Screw conveyor transports materials along pipelines through spiral blades. It is suitable for transporting powdery or granular materials and is commonly used in chemical, food and other industries.

Bucket conveyor: Bucket conveyor uses barrels or buckets to load and transport materials. It is suitable for transporting granular and bulk materials and is commonly used in agriculture, building materials and other fields.

Conveyor working principle

Material loading: Materials are loaded into the feed end of the conveyor, usually through loading buckets, conveyor belts and other devices.

Conveying process: The belt starts to run under the action of the driving device, transporting the material along the conveying line to the destination. The driving device usually uses an electric motor or a hydraulic motor.

Unloading: When the material reaches its destination, the material is unloaded from the conveyor through the unloading device, which can be an inclined conveyor belt, loading hopper, etc.

Recycling: The unloaded conveyor can be restarted and recycled for material transportation in the production process.

Conveyor Application

Mining Industry: In the mining field, belt conveyors are widely used in coal mines, mines and other places to transport large materials such as coal and ore.

Logistics and warehousing: In the logistics industry, roller conveyors are often used in warehousing facilities for the loading, unloading and transportation of goods, improving logistics efficiency.

Manufacturing industry: In the manufacturing industry, screw conveyors are often used to transport powdery raw materials, such as powders, granules, etc., and play a role in connecting different processes on the production line.

Construction industry: In the construction field, barrel conveyors are often used in concrete mixing stations, sand and gravel yards and other places to transport concrete, sand and gravel and other raw materials.

As an important equipment in modern industrial production, conveyors improve production efficiency, reduce labor costs, and improve the working environment through automated material transportation. With the continuous development of science and technology, it is believed that conveyors will play an increasingly important role in industrial production and make greater contributions to the development of industrial intelligence and automation.

Product Advantages

1. Low operating cost and stable performance.

High productivity, all of which are conducive to reducing production costs. Reliable operation, in many important production units that require continuous operation, it can work continuously one after the other. Low power consumption, because there is almost no relative movement between the material and the conveyor belt, not only the running resistance is small, but also the wear and breaking of the load are small.

2. Strong adaptability and diverse choices.

According to the requirements of the technological process, the belt conveyor can flexibly receive materials from one or more points, and can also discharge materials to multiple points or several sections. When feeding material to the conveyor belt at several points at the same time (such as the conveyor under the coal bunker in the coal preparation plant) or feeding the conveyor belt through uniform feeding equipment at any point along the length of the belt conveyor, the belt conveyor The machine becomes a main conveying trunk line. The transmission line has strong adaptability and flexibility. The length of the line is determined according to the needs. It can be as short as a few meters and as long as more than 10km. It can be installed in small tunnels, and can also be erected over areas with chaotic and dangerous ground traffic.

3. Reduce the difficulty and have high versatility.

The belt conveyor can take material in the tunnel below the coal storage yard, and can also mix different materials from each pile when needed. Material can simply be unloaded from the conveyor head.

Our Factory

Company Profile

The company is located in Xingtang Economic Development Zone, Shijiazhuang, Hebei Province. The company has been committed to the research, design, development and manufacturing of various types of dust collectors, magnetic separators, vibrating screens, dryers, sand washers, conveyors, etc. Mining Equipment. The company adheres to the concept of "technology first, integrity first".

Technical strength:

Huaicheng Machinery has an efficient team composed of experienced engineers and technical experts, constantly pursuing technological innovation and product upgrades. In terms of mechanical structure design and automated control systems, Huaicheng Machinery has always maintained a leading position in technology.

Manufacturing process:

Huaicheng Machinery has advanced production equipment and a strict quality control system to ensure that every piece of equipment can meet customer requirements. The company focuses on the refinement and standardization of production processes, using advanced processing techniques and sophisticated testing methods to ensure product stability and reliability.

Customer service:

Huaicheng Machinery always puts customer needs first and takes satisfying customer needs as its own responsibility.

Looking to the future:

As an enterprise that constantly pursues excellence, Huaicheng Machinery will continue to adhere to the purpose of "quality first, customer first", continuously improve its technical strength and service levels, and provide customers with better industrial solutions. In the future, Huaicheng Machinery will continue to be committed to technological innovation and product upgrading, and work hand in hand with customers to create a better future together!

Hebei Huaicheng Machinery Equipment Co., Ltd. looks forward to working with you to create brilliance together!

Company Profile

Customer Visit

Overseas Delivery

Exhibition

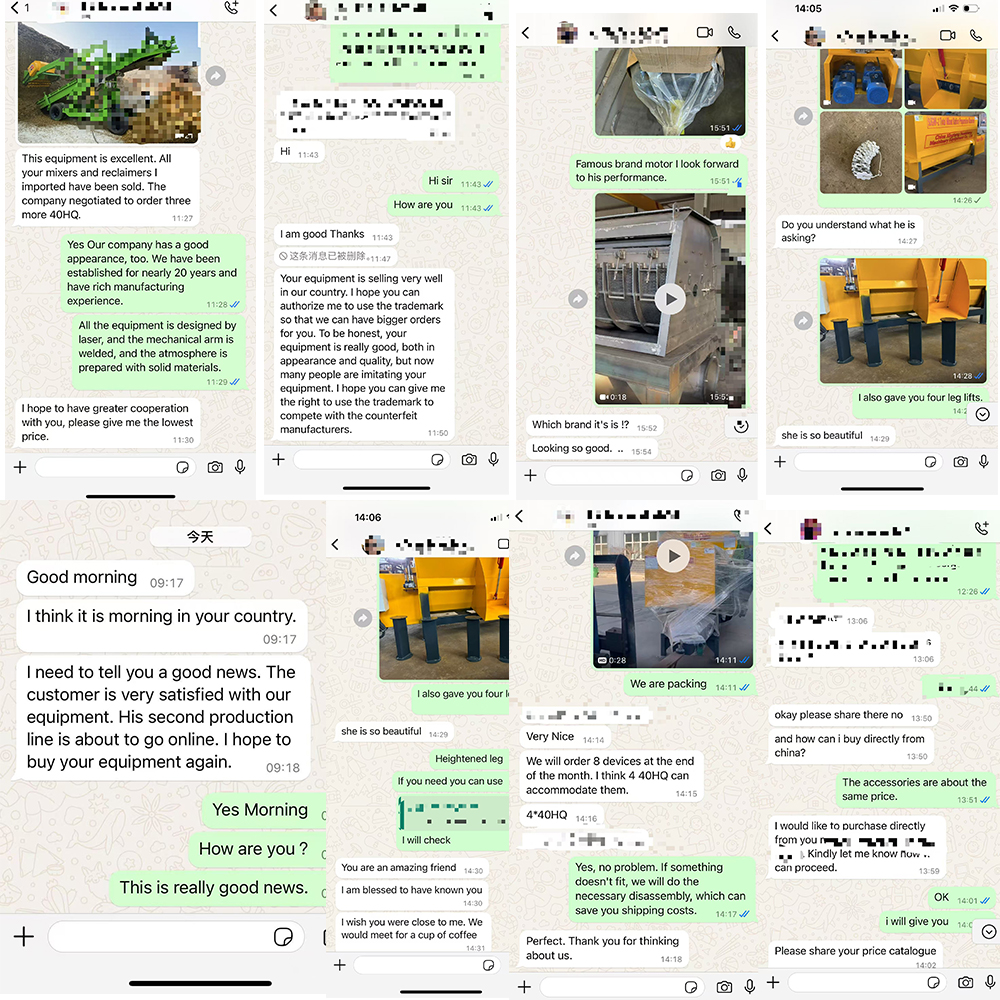

Feedback