1. Safety distribution box: support one-button start, button operation, providing safety guarantee for the whole machine

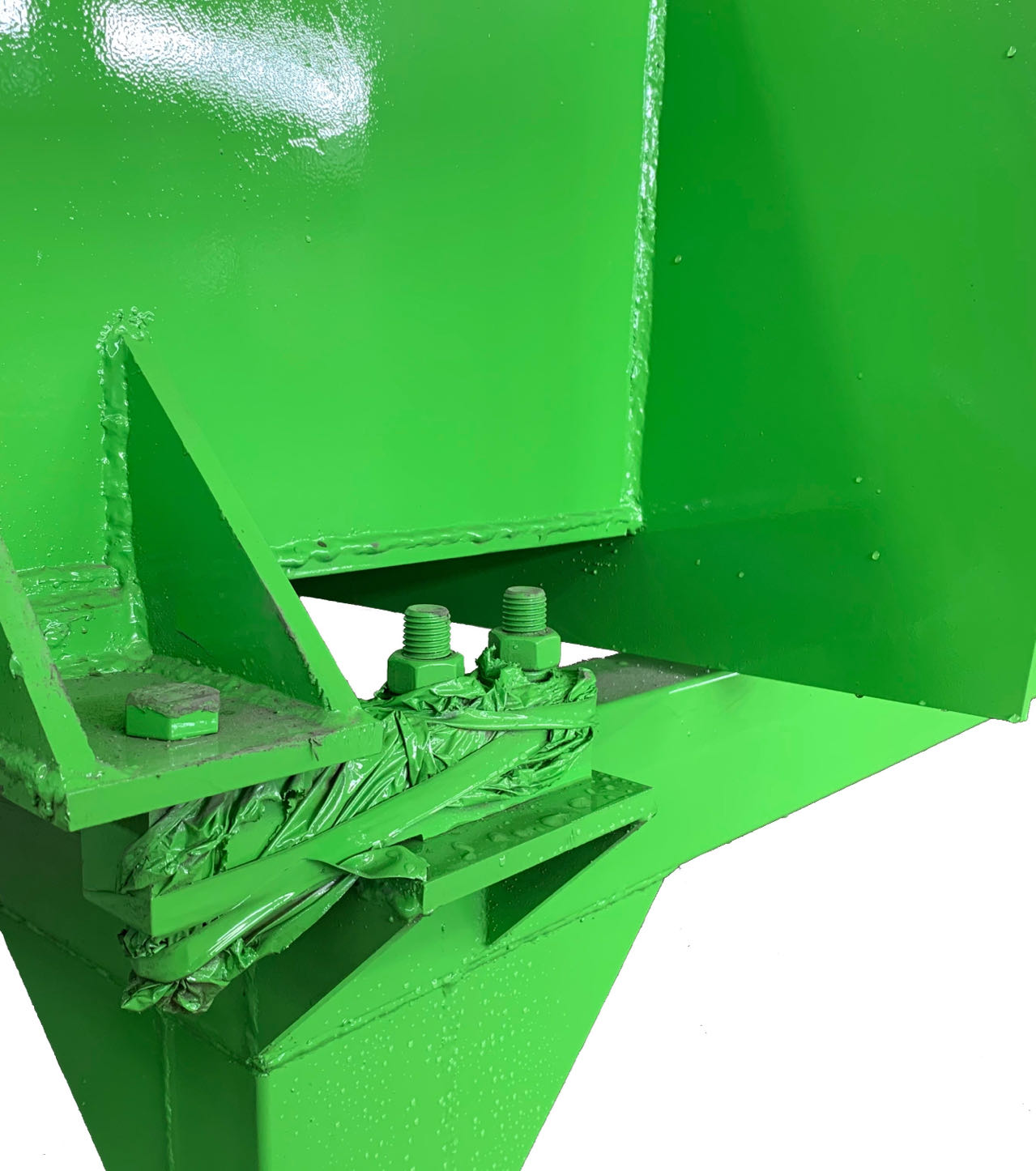

2. Independent hydraulic lifting system: independent oil pump drives a small handle to control the speed of the hydraulic grass outlet

3. Electronic weighing sensor: 8 tons of high-precision electronic weighing sensor can accurately calculate the ratio of concentrate and forage to realize scientific farming

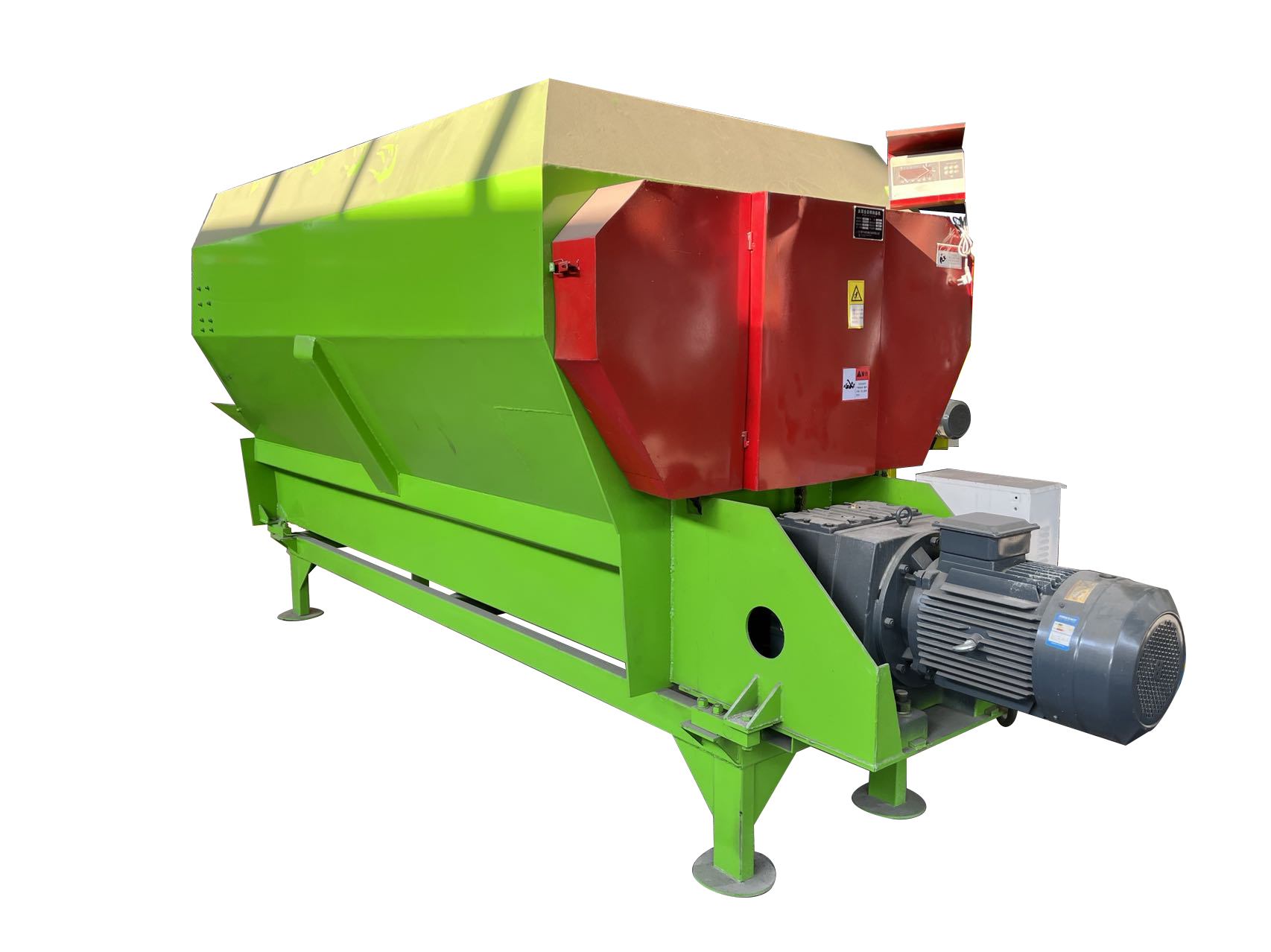

Tmr Horizontal Feed Mixer Feed Mixer Kneading Wire Cutting Mixing Machine

Core Introduction

otal Mixed Diet Mixer: A powerful tool for improving feed production efficiency and quality

Hebei Xingtang Huaicheng Machinery Equipment Co., Ltd.

With the development and modernization of animal husbandry, feed production technology is also constantly innovating. As an important piece of equipment in modern feed production, the fully mixed ration mixer plays a key role.

Technical Parameters

| Type | Dimensions(mm) | Motor | weight |

| 9JGW-4 | 3000*1750*2070 | 11*2 | 1500 |

| 9JGW-7 | 4300*1750*2100 | 22 | 2500 |

| 9JGW-9 | 4400*2350*2700 | 30 | 3200 |

| 9JGW-12 | 4800*2300*2000 | 22*2 | 5000 |

Principles and workflow

1.Feeding: Various feed raw materials are input into the mixer through the feeding system.

2.Weighing and measuring: According to the preset formula, the mixer automatically weighs and measures various raw materials.

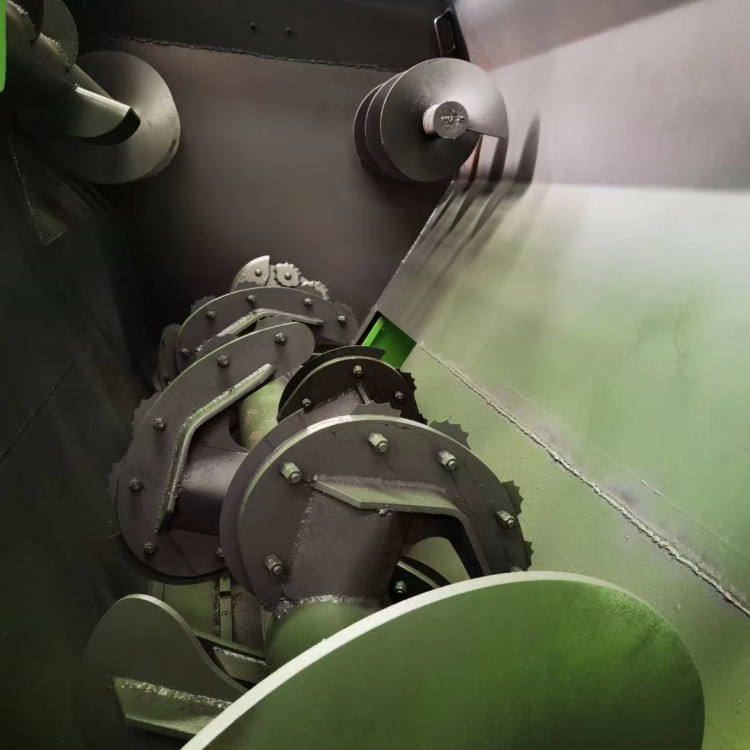

3.Mixing: Various feed ingredients are transported to the mixing chamber and mixed through mixers and other equipment.

4.Unloading: After mixing is completed, the feed is output through the unloading port to be used to feed animals.

Advantages and features

High efficiency and energy saving: fully automated operation, reducing labor costs, improving production efficiency and saving energy consumption.

Uniform mixing: Advanced mixing technology is used to ensure that various raw materials are fully mixed and the feed quality is more uniform.

Precise formula: The batching system can accurately measure various raw materials to ensure the accuracy of feed formula.

Easy to operate: The operation interface is friendly and easy to master, which reduces the technical requirements of the operator.

Multi-functional: The mixed formula can be adjusted according to different needs to adapt to the feeding needs of different types of animals.

Impact on feed production

1.Improve production efficiency: Automated operation reduces manual intervention, greatly improves the efficiency of feed production and reduces production costs.

2.Optimized feed formula: The precise batching system makes the feed formula more scientific and reasonable, improving the growth efficiency and production performance of animals.

3.Ensure feed quality: high mixing uniformity and accurate raw material composition ensure the quality and nutritional balance of the feed.

4.Reduce feed loss: High mixing uniformity effectively reduces feed waste and loss.

5.Improve the competitiveness of the animal husbandry industry: Efficient production methods and high-quality feed give the animal husbandry industry more advantages in market competition.

As an important piece of equipment in modern animal husbandry production, the fully mixed ration mixer plays an irreplaceable role in improving feed production efficiency and quality. With the continuous advancement of science and technology and the expansion of application scope, it is believed that the total mixed ration mixer will play a more important role in the development of animal husbandry and provide solid support for the modern development of animal husbandry.

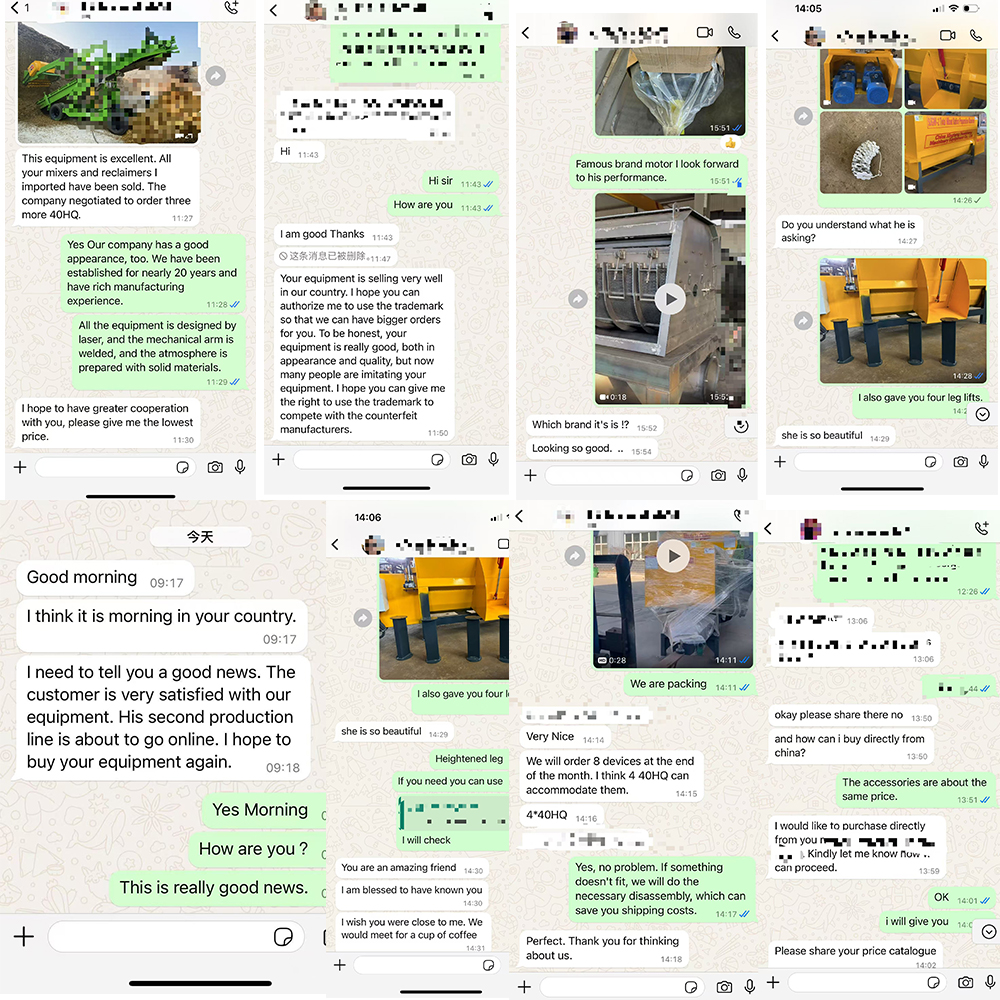

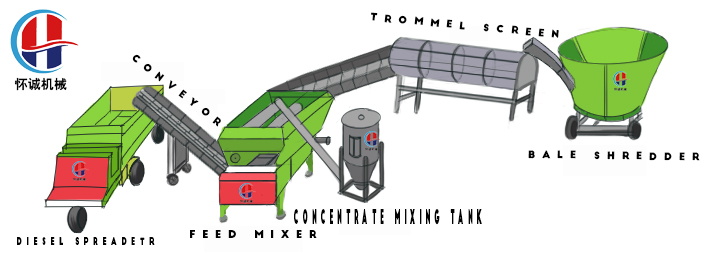

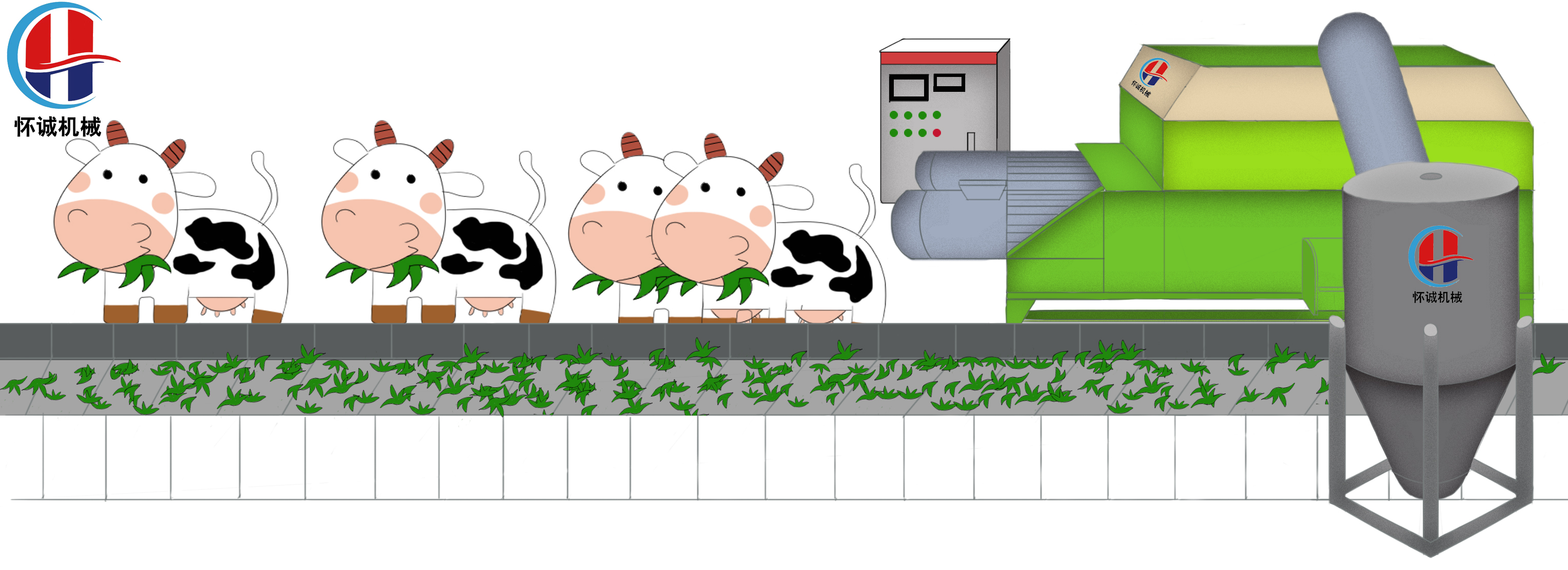

Mechanized farming case display:

After the automatic distribution box is opened, you can set the mixing time of the mixer, or set the default time, click Start, the mixer starts, the mixing starts to run, the grass enters the silo through the conveyor, the flour mill, and the fine material tank are opened simultaneously. After the fine material is mixed, it will automatically start feeding in the mixer. When the mixer is finished mixing, the hydraulic lifting door will automatically open and start discharging. At this time, the conveyor will automatically open and start running. The total length is 97 meters. After the material is discharged, the conveyor will stop running, and the bin door will be automatically closed. According to the degree of mixing of the grass, the reasonable mixing time can be appropriately modified and saved. When it is used next time, directly according to the Set the content and start with one key. The breeding system is our company in After the on-site inspection of the customer's breeding factory, it was designed according to the customer's requirements. The whole process of feeding cattle and sheep is automated, and the original drinking trough is replaced by a conveyor. It is also equipped with a water pump for water supply, a spray tower disinfection tank, cooling and disinfection, and a manure scraper. Carry out excrement cleaning work, save labor, and one person can feed hundreds of cows.

Show more details

Advantages

1. The concentrated roughage is evenly mixed to improve the palatability of the feed and avoid the occurrence of picky eating and nutritional imbalance in dairy cows;

2. It is beneficial to the synthesis of carbohydrates and carbohydrates, and to improve the utilization rate of protein;

3. Enhance rumen function, maintain the stability of rumen pH value, and prevent rumen acidosis;

4. It can maximize the dry matter intake of dairy cows and improve the conversion rate of feed;

5. According to the quality and price of roughage, flexibly adjust and effectively utilize non-roughage;

6. Reduce labor, improve breeding efficiency, and make animal feeding management more accurate;

7. It can make full use of local raw material resources to reduce the cost of feed;

8. It is beneficial to the large-scale production of cattle farms;

9. Conducive to epidemic prevention of dairy farms and reduce the incidence of diseases.

Company Profile

Customer Visit

Overseas Delivery

Exhibition

Feedback